Sludge drying

An overview of sludge drying − an introduction to sludge drying theory and technologies

Your web browser is out of date.

Update your browser for better security, speed and to get the best experience on this website.

Belt dryers comprise a conveyer belt which is fed with the dewatered sludge. The sludge solids are slowly transported by the belt through a stream of heated air, generally at 80-180 °C. They permit an additional element of process control to the usual parameters of sludge feeding rate and heat input, since the belt speed can be adjusted to change the dryer residence time.

An overview of sludge drying − an introduction to sludge drying theory and technologies

Processes where moisture is removed from sludge as water vapour are known as 'sludge drying'

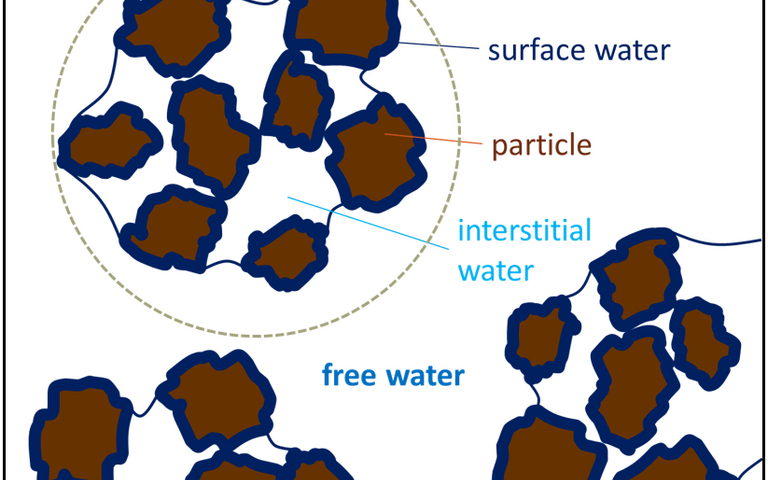

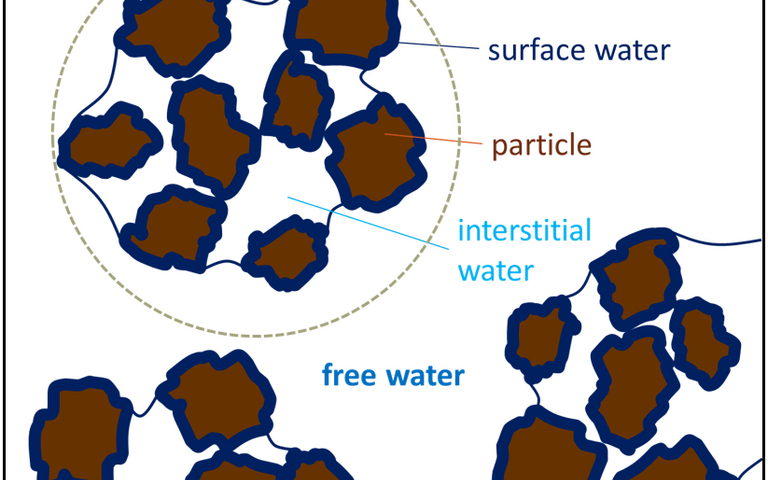

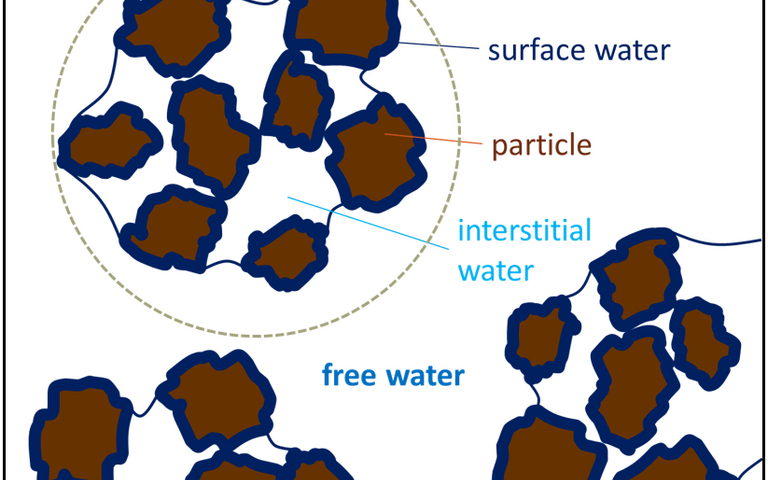

When sludge dries, it goes through three different phases as the water evaporates

Sludge drying processes operate at solids temperatures of 60-93 °C to encourage water to evaporate and leave a solid residue

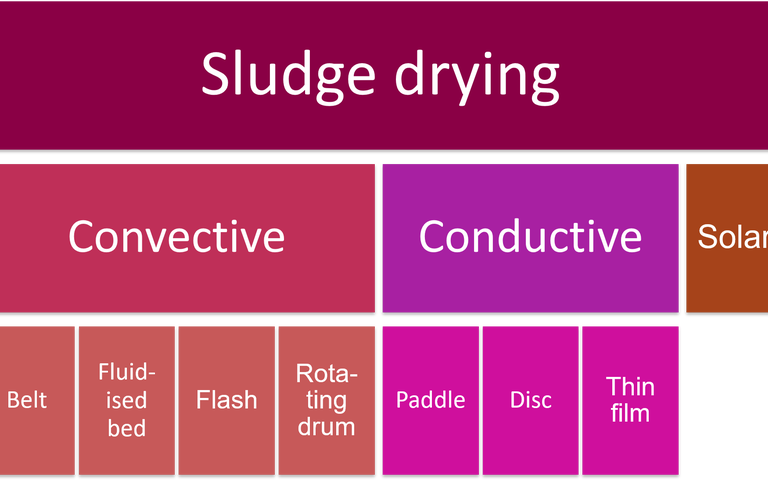

Sludge drying processes are generally configured as convective, conductive, or as solar dryers

Convective sludge dryers are the most commonly used type of dryer for sewage sludge

Huber's animation of sewage sludge drying using a belt dryer at Innsbruck wastewater treatment works.

Convective (or direct) dryers remove moisture from sludge by bringing the sludge particles into direct contact with hot gas

Flash dryers use a rapid stream of rising hot air which both suspends and dries the solids.

In fluidised-bed dryers the sludge particles are gently agitated and heated by a stream of upward-flowing pre-heated gas

Rotating drum dryers have a drum rotating at 4-8 RPM through which the sludge passes along with a stream of warm air

For conduction drying, the sludge is heated indirectly by bringing it into contact with a heated surface

Disc dryers are based on vertical externally-heated discs or rings rotating in the sludge as it passes through the dryer.

Paddle dryers are based on externally-heated paddles rotating in the mass of sludge solids held in a stationary vessel

Solar dryers comprise large greenhouses in which sludge is dried under the ambient conditions of the building.

Pelletizers

Conditioning is the pretreatment of sludge upstream of thickening and dewatering to promote solid-liquid separation

Thickening processes concentrate the sludge by removing part of the free water, such that the product can still be pumped

Dewatering processes mechanically remove a significant proportion of the sludge water to produce a 15-45% cake product

In sludge drying the sludge moisture is removed as water vapour by heating, generating a pelleted or powdered product

Sludge stabilisation − alkaline stabilisation, lime and solids dosing, plus anaerobic and aerobic digestion

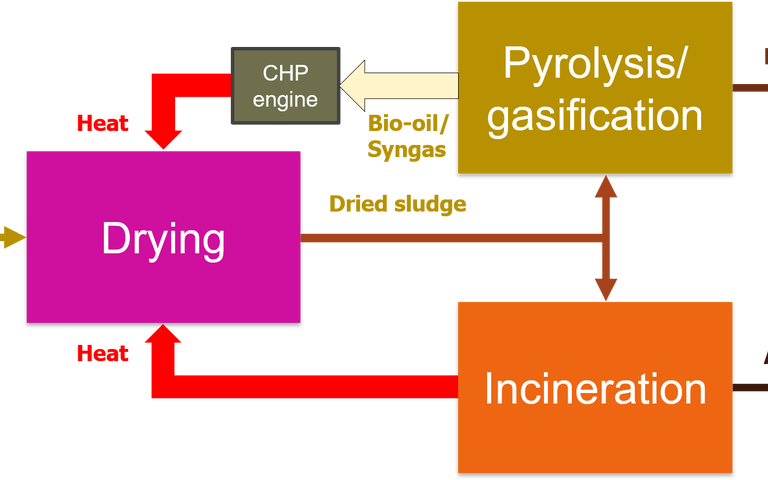

Thermochemical methods are used to either significantly reduce the sludge solids content or pre-treat sludge upstream of AD

Sludge is the main waste stream from the treatment of wastewater