Sludge thermochemical treatment − an overview

Introduction to thermochemical methods

Thermochemical methods are used for either:

- significantly reducing the sludge solids content, or

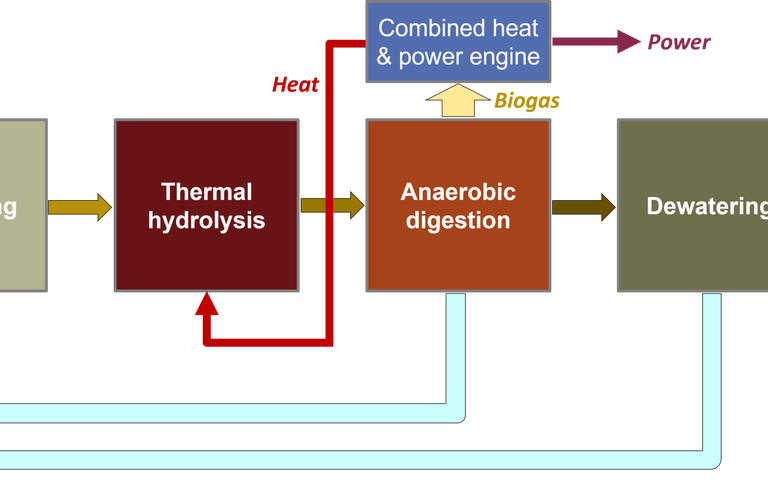

- pre-treating sludge upstream of anaerobic digestion (AD) to increase the biodegradability of the organic carbon

As with stabilisation and drying processes, thermochemical processes produce a stable sludge product. When operated at elevated temperatures, i.e. for solids destruction rather than AD pre-treatment, they provide energy recoverable either as heat or a combustible gas or liquid.

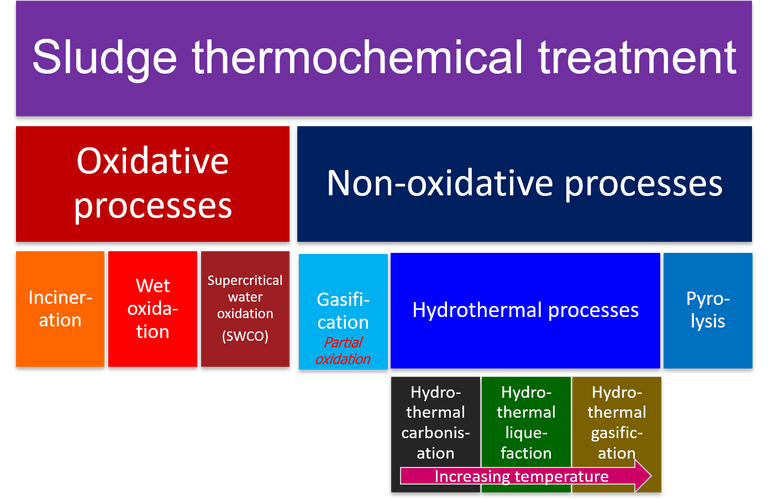

There are two chemical states by which the solids content of sludge can be reduced thermochemically:

- oxidative and

- non-oxidative.

As such, the thermochemical process types are analogous to the biochemical digestion methods for solids destruction which take place in the presence (aerobic digestion) or absence (anaerobic digestion) of air.

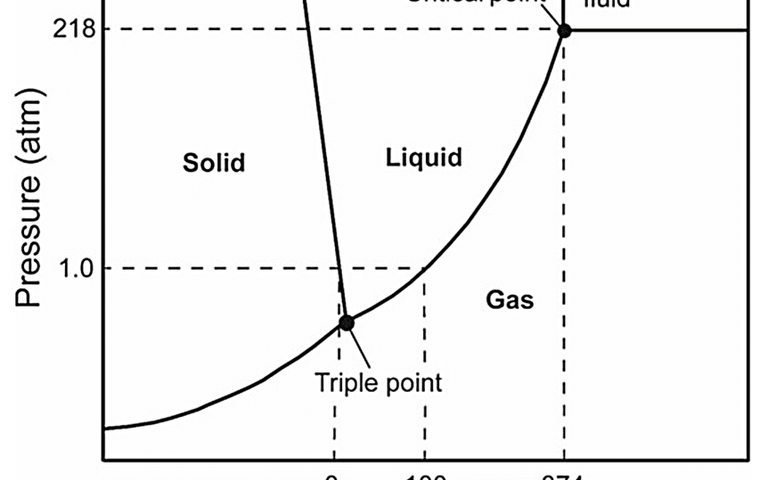

Oxidative methods for sludge thermochemical treatment comprise incineration, wet air oxidation (WAO) and supercritical water oxidation (SCWO). These processes convert the combustible organic matter to primarily carbon dioxide and water, along with other gaseous oxidised byproducts (such as nitrogen oxides or NOx) present at lower concentrations, and a solid residue. The methods differ in terms of the operational temperature and pressure, the required feed sludge water content, and the nature and concentrations of gaseous and solid products generated. Whereas incineration and SWCO require a substantially dry feed, WAO is conducted in the presence of water.

Non-oxidative methods include hydrothermal processes (HTPs), pyrolysis, and gasification, where gasification is based on partial oxidation of the organic carbon. Whereas pyrolysis and gasification require a substantially dry sludge product, HTPs are effective for sludges having a significant water content.

Other key aspects of a thermochemical process comprise:

- the net energy consumption or generation, and

- the quantity, quality and characteristics of the thermally generated products, in particular for the non-oxidative methods.

All thermochemical processes generate solid and gaseous product streams. The solid streams can be referred to as an ash for an incineration process, or a biochar or hydrochar for the non-oxidative processes, depending on whether the process is conducted in the absence or presence of water respectively. For some process types, the gas stream is partially condensed to produce a liquid (bio-oil) which provides a source of energy and/or reusable chemicals.

HTPs are defined by the target product generated. Hydrothermal carbonisation (HTC) processes are designed to generate the solid (hydrochar) fraction as the primary product. Hydrothermal liquefaction (HTL) and gasification processes target the liquid (bio-oil) and gas (referred to as syngas) products, where the primary product combustible gas from gasification is hydrogen.