Wet (air) oxidation of sludge

Introduction to wet oxidation of sludge

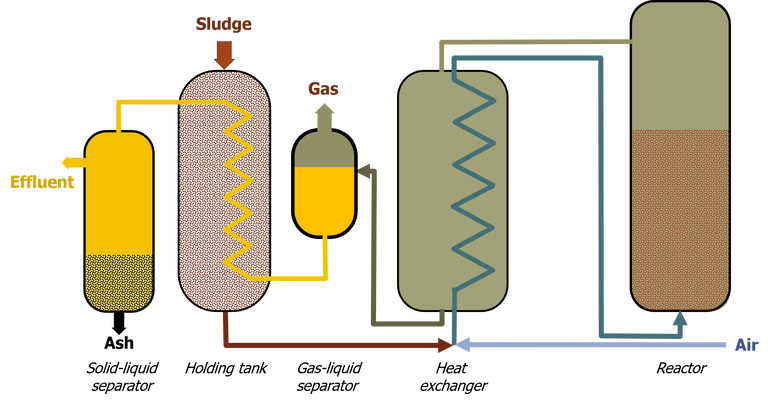

Wet oxidation of sludge − or more commonly, wet air oxidation (WAO) if carried out in air rather than pure oxygen − is the thermal degradation, hydrolysis and oxidation of organic matter at high temperatures and pressures.

Unlike incineration − the most established oxidative thermal method − the wet air oxidation process does not generate secondary pollutants such as dioxin, furans, NOx

(oxides of nitrogen) and SO2 (sulphur dioxide). Instead, the process can be operated either to enhance the biodegradability of the sewage sludge or to substantially mineralise the organic matter (i.e. convert it to bicarbonate and carbon dioxide).

WAO is an established process, having been originally commercialised in the 1960s. Hundreds of WAO plants have been installed globally for the treatment of challenging industrial effluents containing bio-refractory organics and/or toxic compounds which cannot be treated by classical biological processes. An example is the ZimproTM process from Siemens. There exist a few examples of full-scale WAO plants used for sewage sludge specifically, which employ the TOP® process technology from the company 3V Green Eagle.

WAO operates in an aqueous environment and therefore does not demand drying of the sludge. Sludge destruction by WAO typically employs temperatures between 260 and 320 °C at pressures of 20−150 bar and residence times of 0.25−2 h. Under these aggressively oxidative conditions, a COD removal of 70−85% is obtained, with removal increasing with operating temperature and retention time.

The high temperatures at which WAO operates demand correspondingly high pressures to ensure that the water remains in the liquid phase (rather than the gas phase, as would arise at reduced pressures) and that the salts therefore remain dissolved. Salts precipitation has been identified as being the possible cause of corrosion in early commercialised WAO technologies. Pressurisation also increases the dissolved oxygen concentration, adding to the oxidative potential of the process but also to the corrosion propensity.

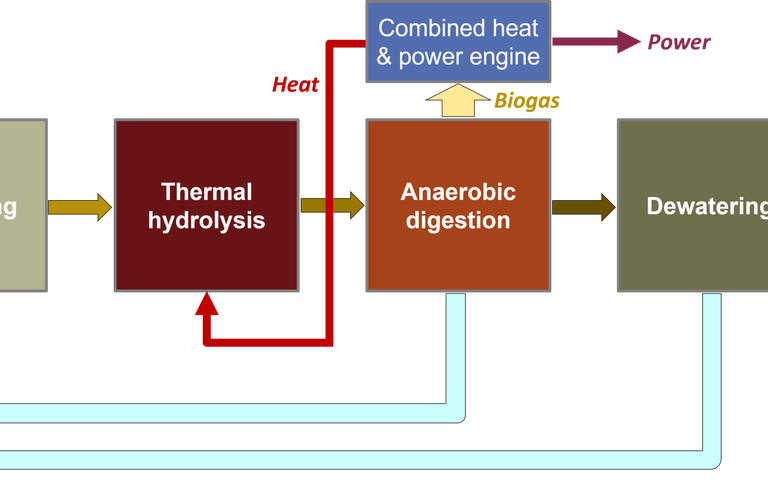

WAO application upstream of anaerobic digestion is intended to enhance the biodegradability of the organic matter in the downstream AD reactor. For this duty, lower temperatures (100–200 °C) and pressures (<20 bar) are used, sometimes with the addition of a catalyst. The WAO performance is measured in terms of the increase in either the liquid−phase organic carbon, or the subsequent removal of volatile suspended solids (VSS) by the AD process.

Most recently, there has been interest in the potentially high-value intermediate oxidation products (low molecular weight organic compounds such as acetic and propionic acid) generated by WAO. While these carboxylic acids are produced in appreciable concentrations by the WAO process, extracting and purifying them for reuse remains a challenge.