What is sludge?

Overview of sludge characteristics

Sludge characteristics depend on both the original feedwater quality and the type of the unit operation from which the sludge is discharged.

For conventional municipal wastewater treatment, the two main sludge streams are:

- from the primary sedimentation stage, producing primary sludge, and

- the secondary biological treatment stage, producing waste activated sludge (WAS) if the biological treatment is based on the activated sludge process [links to The MBR Site].

Regardless of its origins, sludge contains water, dissolved organic and inorganic materials and suspended solids. The suspended solids normally make up 2−5% of the sludge for municipal wastewater sludge.

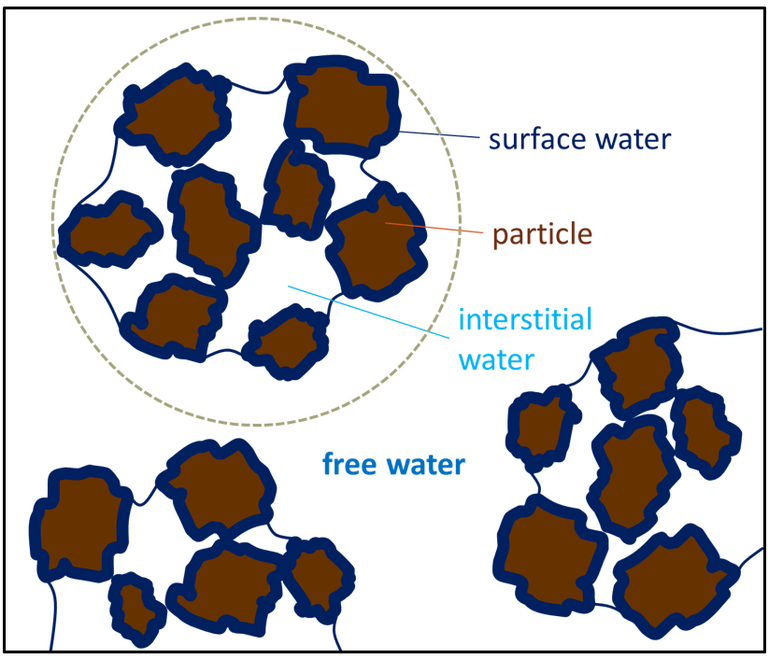

Sludge water concentration

A key part of sludge treatment is the reduction of its volume by reducing the water content. The water in sludge exists in various forms:

- Free or unbound water is the fraction not associated with the solids or flocs – assemblages of particles held together by biological and organic polymeric materials. This water fraction can potentially be separated by mechanical treatment (thickening and dewatering). The free water makes up around 70% of the water in municipal wastewater sludge.

- Interstitial water refers to the water bound by capillary forces between the sludge flocs or else is trapped in crevices in the flocs, and so is sometimes referred to as floc water. This water may be released when the floc is fragmented such as under the influence of shear forces. Some interstitial water may be removed by mechanical means such as by centrifugation.

- Surface or vicinal water is the fraction associated directly with the solid particles and is bound to the particle surface by hydrogen bonding. This water component cannot be removed by mechanical means.

- Intercellular water refers to water held within the micro-organism cells, or else is chemically bound within the particle structure. As with the surface or vicinal water, it cannot be removed mechanically. It is only released by thermal methods which destroy the particles and cells and extract the water as a vapour.

Sludge content

Sludges of different qualities are produced from different biological unit operations. A key sludge quality parameter is its % dry solids (%DS) content, which is 100% minus the percentage water content. The %DS reflects the extent to which the sludge is consolidated. In the absence of any biological degradation of the solids, the sludge volume decreases with decreasing water and correspondingly increasing DS content.

The second key sludge quality parameter, with reference to its processing, is the degradable organic matter content, usually expressed as the chemical oxygen demand (COD) rather than as the biochemical oxygen demand (BOD).

Regarding COD concentration in sludge processing:

- for sludge production or generation from a wastewater treatment unit operation, the amount of suspended solids is often normalised against the COD concentration in the feedwater to that unit operation, giving units of kgSS/kgCOD

- for thermochemical and anaerobic digestion sludge processing operations, the amount of methane (kgCH4) or calorific content (MJ) generated is usually normalised against the COD concentration in the feed sludge to these operations.

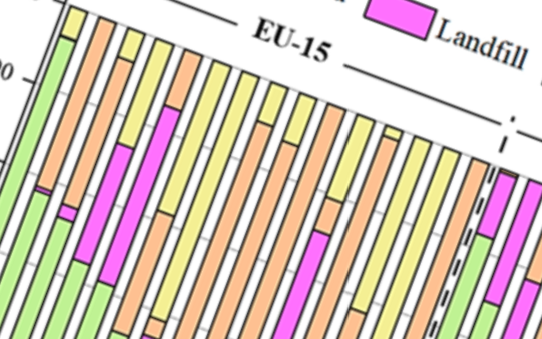

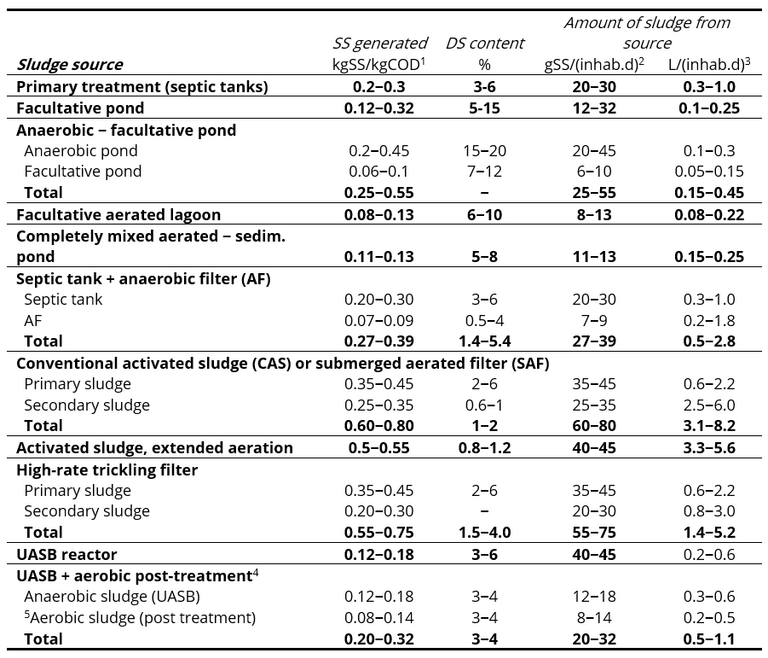

Table 1. Characteristics of sludge generated from different wastewater treatment processes (Andreoli et al, 2007)

Values refer to digestion + thickening for ponds, septic tanks, UASBs, AFs

1Amount of suspended solids generated per kg feed COD

2Assumes 0.1 kg/(inhabitant.d) and 0.06 kgSS/(inhabitant.d)

3L sludge/(inhabitant.d) = [(gSS/(inhabitant.d))/%DS] x 100/ρsludge, where ρsludge = sludge density ~ 1000 kg/m3

4Based on CAS (conventional activated sludge), SAF (submerged aerated filter) or TF (trickling filter)

5Aerobic sludge withdrawn from UASB (upflow anaerobic sludge blanket) clarifier tank, after mass & volume reduction via digestion & thickening occurring within the UASB reactor; the aerobic excess sludge entering the UASB is also smaller since, in this case, the solids loss in the secondary clarifier becomes more influential.

Table 1. Characteristics of sludge generated from different wastewater treatment processes (Andreoli et al, 2007)

Values refer to digestion + thickening for ponds, septic tanks, UASBs, AFs

1Amount of suspended solids generated per kg feed COD

2Assumes 0.1 kg/(inhabitant.d) and 0.06 kgSS/(inhabitant.d)

3L sludge/(inhabitant.d) = [(gSS/(inhabitant.d))/%DS] x 100/ρsludge, where ρsludge = sludge density ~ 1000 kg/m3

4Based on CAS (conventional activated sludge), SAF (submerged aerated filter) or TF (trickling filter)

5Aerobic sludge withdrawn from UASB (upflow anaerobic sludge blanket) clarifier tank, after mass & volume reduction via digestion & thickening occurring within the UASB reactor; the aerobic excess sludge entering the UASB is also smaller since, in this case, the solids loss in the secondary clarifier becomes more influential.

For simple solids separation water/wastewater treatment unit operations, such as the primary sedimentation step of the conventional activated sludge (CAS) [links to The MBR Site], trickling filter (TF), or submerged aerated filter (SAF) processes, the kgSS generated per kgCOD is relatively high at 0.35−0.45. The values are lower (0.2−0.35) for the second, aerobic biological stage of these processes because some of the COD is mineralised (i.e. converted to bicarbonate or CO2). The values are lower still (0.12−0.3) for anaerobic processes, like the septic tank and upflow anaerobic sludge blanket (UASB) because these processes biologically degrade more of the organic carbon.

The biological conversion of organic matter to sludge solids by wastewater treatment therefore depends on the type of unit process. It is also influenced by the process operating conditions, and the characteristics of the feedwater.