Sludge treatment - the anaerobic digestion process

Introduction to anaerobic digestion

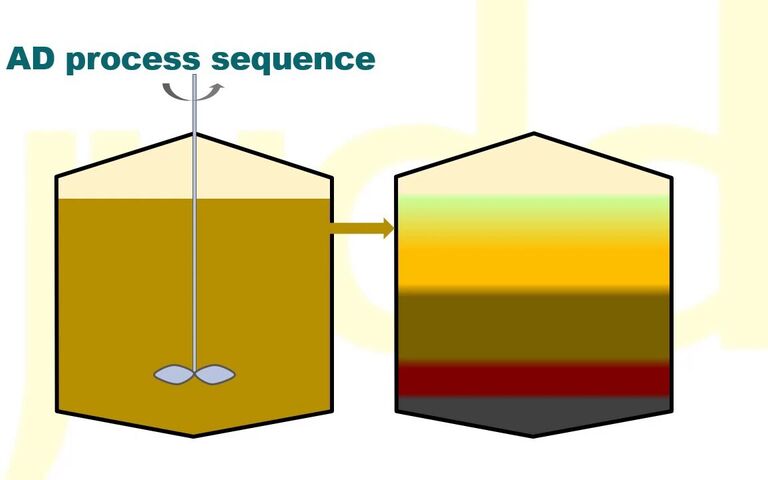

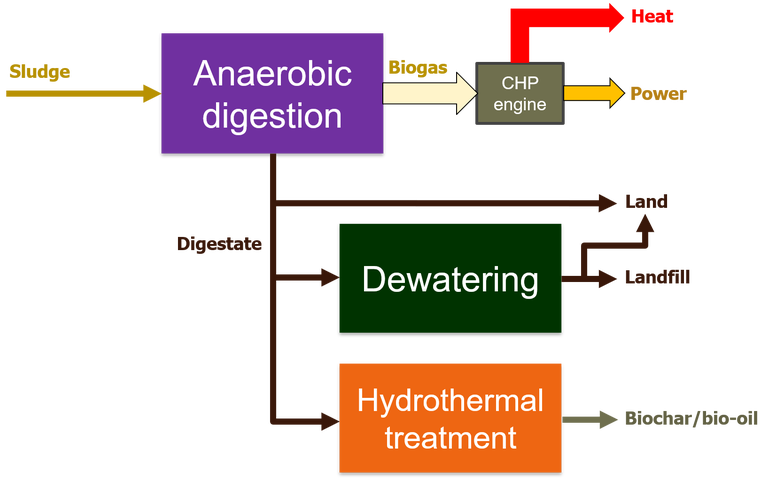

Anaerobic digestion (AD) is the most extensively employed sludge stabilisation process. AD stabilises the sludge biologically in the absence of air. In doing so, it reduces the amount of volatile solids by their conversion to a biogas (methane CH4, carbon dioxide CO2 and water H2O). The biogas then demands further processing for recovery and reuse of its methane content. The stabilised solids product can be used for soil conditioning in much the same way as the solids product generated from lime dosing.

AD can be operated either:

- at moderate − or mesophilic − temperatures (30−39°C optimum range), or

- at elevated − or thermophilic − temperatures (49−57°C).

The precise optimum temperature within these ranges depends upon the desired outcomes in terms of biogas production and composition, solids reduction and energy efficiency.

Operation below ~20°C is referred to as psychrophilic. Operation at such low temperatures can be more energy efficient. However, since biochemical reaction rates and the corresponding biogas production rates decrease at lower temperatures, the required tank size increases accordingly.

Anaerobic digestion - an introduction

As with most sludge and wastewater unit processes, the design and performance of AD depends on the feed characteristics. In municipal wastewater treatment AD is most often used to treat the waste solids discharged from the activated sludge-based process [links to YouTube.com], both the primary and the secondary (waste activated) sludge streams. The characteristics of the streams generated from the AD process (i.e. the biogas and the stabilised solids product), as well as the plant operation, is then influenced by the feed sludge quality. Specifically, since anaerobic digestion is a biological process, it can be adversely affected by high concentrations of toxic or potentially toxic materials, such as sulphates and heavy metals.

Although i) much lower in energy consumption than aerobic digestion/stabilisation and ii) generating less waste while consuming fewer chemicals than alkaline stabilisation, anaerobic digestion is also higher in capital cost and more complex in operation than the alternative stabilisation options. It is favoured at large sites where the operating costs of the alternative processes becomes significant.