Other sludge dewatering processes

Electro-dewatering

Electro-dewatering (EDW) technology provides enhanced removal by non-mechanical means through the application of an electric field.

EDW of sludge removes water from the sludge through the principle of electro-osmosis. Electro-osmosis is an electrophoretic phenomenon, where movement of a solid relative to the surrounding liquid, or liquid within a porous solid, can take place on the basis of the charge at the solid−liquid interface when a direct electric field is applied.

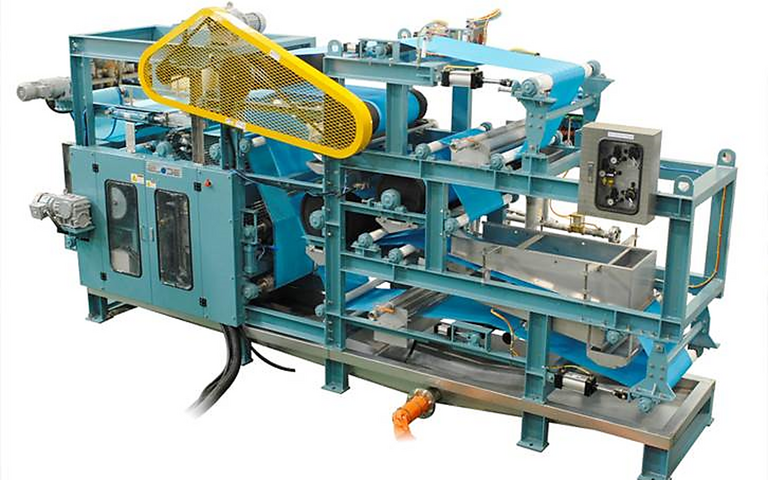

An EDW device comprises a narrow horizontal channel through which the sludge is fed. A direct electric field is placed across the channel, with the anode at the top and the cathode and a filter cloth at the base. The cathode on which the filter cloth sits is porous to allow the water to pass through it.

The application of an electric field causes water to be extracted from the sludge under the influence of the electrophoretic force. No additional no mechanical force is required: the rate of water removal is dependent on the charge at the particle surface and the applied voltage.

A cake of up to 50% dry solids (DS) has been claimed from this method, with an accompanying sludge volume reduction of up to 75% at sludge loading rates of 75−150 kgDS/(m2.h) per m2 dewatering area.

Although the process appears to be very effective, the electrical energy consumption is significant – around 300 kWh per ton of water removed. This limits its application to sludges of relatively low water content, i.e. conventionally dewatered sludges. As such, it competes with thermal drying as a water removal technology, rather than mechanical dewatering technologies whose energy consumption is generally well below 20 kWh per ton water removed.