Sludge pretreatment for anaerobic digestion

An overview of sludge pretreatment for AD

Pretreating sludge upstream of the anaerobic digestion (AD) is sometimes carried out to improve the sludge biological treatability. This is usually achieved through heat treatment, and referred to as thermal conditioning.

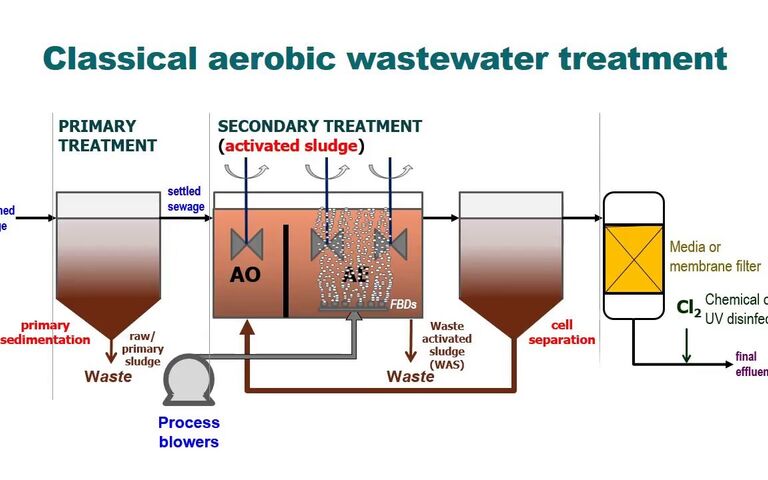

Thermal conditioning is especially favoured for waste activated sludge (WAS) sources. WAS is less readily hydrolysed – the first step of the anaerobic degradation mechanism – than primary sludge, the sludge produced from the initial sedimentation step of conventional municipal wastewater treatment (see video below). This is because the complex microbial structure of the WAS flocs impedes the penetration of enzymes responsible for hydrolysing the organic matter in the microbial cells.

Conventional municipal wastewater treatment

Slower biodegradation implies longer residence times and thus larger tanks for the anaerobic process, incurring a higher cost. It can therefore be cost effective to preheat the sludge to partially degrade it thermally, provided this makes the sludge more biodegradable.

So far, only conventional heating has been employed for pretreating sludge prior to AD, most often based on hydrothermal processes (HTPs). These technologies were originally studied in the 1970s as a means of improving sludge dewaterability. It subsequently became apparent that combining HTP pre-treatment with downstream anaerobic digestion (AD) could improve AD biogas yield as well as remove the sludge odour.

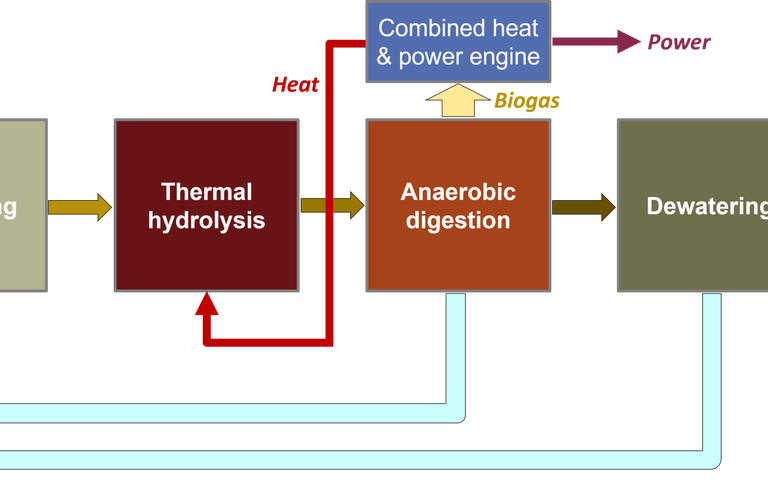

Two widely used commercial processes used for this duty are the Cambi™ Thermal Hydrolysis Process (CambiTHP™) and the Exelys/BioThelys™ process from Veolia. Both processes employ a temperature and pressure of around 165°C and 6–8 bar for a reaction time of 20–30 minutes. Compared with their use for direct sludge thermochemical destruction, the temperatures and pressures used are relatively low at <200 °C and <5 bar respectively.

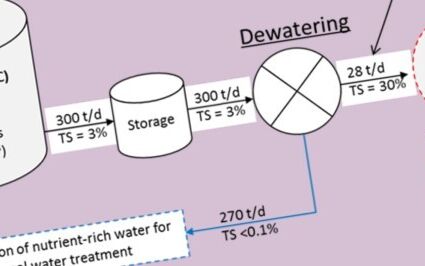

The CAMBI hydrothermal sludge treatment process

Thermochemical treatment under these conditions can significantly increase the AD process efficiency. This is manifested as an increased solubilisation of the COD and/or increased methane generation.

There is also increasing research interest in the use of microwave heating for thermal pretreatment, though so far the costs appear to be prohibitive and no commercial products exist.