Sludge treatment − rotary drum thickening

How rotary drum thickening works

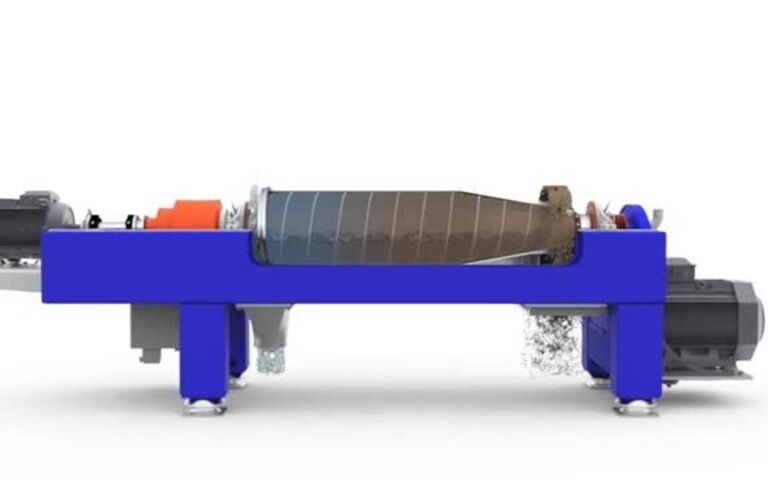

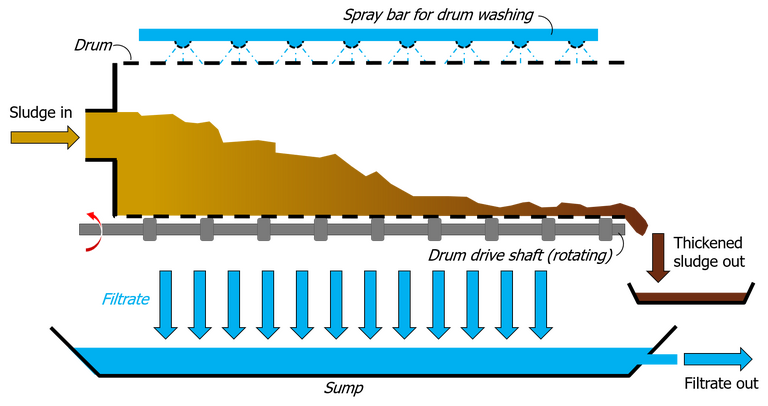

Rotary drum thickening increases the sludge solids concentration (i.e. thickens the sludge) by agitating the solids in a slowly-rotating vessel with porous walls though which the water (or filtrate) drains.

A rotary drum thickener (RDT) is based on the same principle as a gravity belt thickener (GBT), in that water drains from the sludge through a retaining porous medium. For an RDT the porous medium is the cylindrical wall of a 0.5−1.5 m diameter drum which rotates at speeds between 5 and 20 RPM while the sludge continually passes through it.

The porous wall may be fabricated from a range of materials, including polymers, steel and ceramics. A spray system is used to clean the drum and prevent the pores blocking.

Rotary drum thickener, Andritz

RDTs can achieve solids concentrations up to 9% and corresponding solids recoveries of 90−99%, depending on the sludge source and the conditioning employed. Conditioning by polymer dosing is normally conducted in a mixing drum upstream of the RDT.

| Sludge source | Feed | Thickened | Water removed | Solids recovered |

|---|---|---|---|---|

| Primary | 3−6 | 7−9 | 40−75 | 93−98 |

| WAS | 0.5−1 | 4−9 | 70−90 | 93−99 |

| Mixed, primary + WAS | 2−4 | 5−9 | 50 | 93−98 |

| Anaerobically digested | 2.5−5 | 5−9 | 50 | 90−98 |

| Aerobically-digested | 0.8−1 | 4−6 | 70−80 | 90−98 |