Operating an anaerobic digester for sludge treatment

Operating an anaerobic digester

Anaerobic digesters can be operated at different conditions of mixing and temperature. The temperature conditions are normally defined by the types of micro-organisms which are sustained within the temperature range applied, referred to as mesophilic and thermophilic micro-organisms.

Normal parameter value ranges for mesophilic and thermophilic operation for a typical sewage sludge feed are summarised below. Operation outside these ranges (as with low-temperature psychrophilic operation) is possible if the reactor and/or process treatment scheme is appropriately configured or designed.

| Parameter | Meso- | Thermo- | Notes |

|---|---|---|---|

VS Volatile solids | |||

| Temperature, °C | 30−39 | 49−57 | Optimal ranges |

| 35 | 55 | Typical target value | |

| Retention time, d | 15−30 | 5−14 | |

| VS reduction, % | 20−55% | 20−55% | Affected by operating conditions and solids loading & characteristics |

| OLR, gVS/m3/day | 0.5−1.6 | 1.6−6.5 | Low end of range for unmixed reactor; high end for mixed |

The volatile solids (VS) concentration is taken as equating to the organic, biodegradable fraction of the solids, and the VSS the volatile part of the suspended solids. The organic loading rate (OLR) represents the amount of digestible organic matter per m3

sludge fed into the reactor each day.

A further key operating parameter is the pH. The pH must be kept within a specific optimal range to ensure that the process works effectively, as governed by the biochemical mechanism.

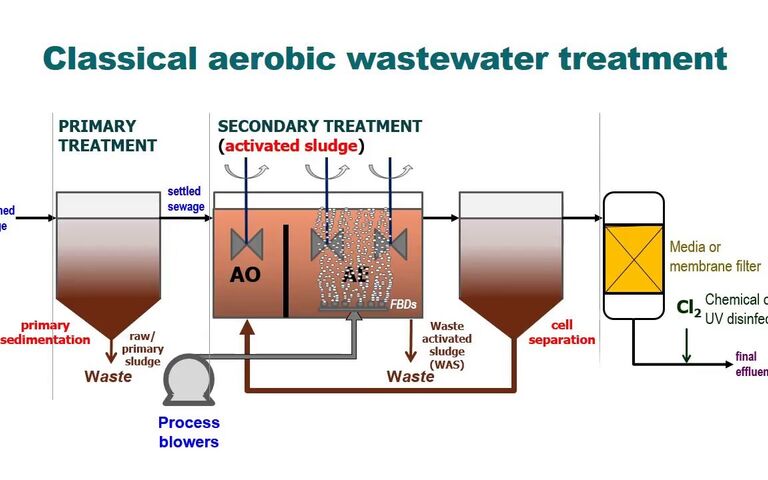

An indication of the range of the characteristics of sludges generated by, or discharged from, the various unit operations in a municipal wastewater treatment scheme can be obtained from reviewing data from a single source, such the Ontario Government’s Design Guidelines For Sewage Works: Sludge Stabilisation, Government of Ontario.

| Source | Liq. Sludgea | Solids concentn. %b − range | Solids concentn. %b − average | VSSc | DS − g/m3,d | DS − g/(cap·d)e | DS decr. % |

|---|---|---|---|---|---|---|---|

DS Dry solids | |||||||

| Primary sedimentation + conventional activated sludge (CAS) + AD | |||||||

| Undigested (no P Removal) | 4.0 | 2–7 | 4.5 | 65 | 160 | 82 | |

| Undigested (w. P Removal) | 5.0 | 2–6.5 | 4.0 | 60 | 220 | 100 | |

| Digested (no P Removal) | 2.0 | 2–6 | 5.0 | 50 | 115 | 52 | 37% |

| Digested (w P Removal) | 3.5 | 2–6 | 4.0 | 45 | 150 | 68 | 32% |

| Primary sedimentation + AD | |||||||

| Undigested (No P Removal) | 2.0 | 3.5–6 | 5.0 | 65 | 120 | 55 | |

| Undigested (With P Removal) | 3.2 | 3.5–7 | 4.5 | 65 | 170 | 77 | |

| Digested (No P Removal) | 1.1 | 5–8 | 6.0 | 50 | 75 | 34 | 38% |

| Digested (With P Removal) | 1.6 | 5–8 | 6.0 | 50 | 110 | 50 | 35% |

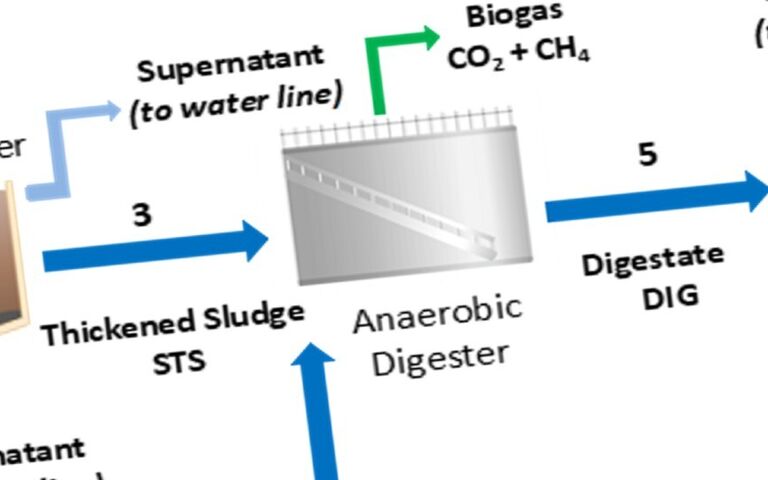

A key anaerobic digestion operational performance parameter is the amount of methane gas product generated, normally referred to as the methane/gas yield. This is expressed either as the mass of methane per unit mass of volatile solids, or as a percentage.

The other key parameter is the net energy consumption or generation in kWh. This relates to the latent energy of the sludge feed, expressed as the calorific value in kWh per ton of sludge dry solids (DS). In general, the anaerobic digestion process is energy positive: there is more energy provided by the sludge than that required to maintain the AD reactor at the required temperature.