Centrifugal sludge dewatering

How centrifugal sludge dewatering works

Centrifugation is used for both thickening and dewatering of sewage sludge, where dewatered sludge has a higher dry solids (DS) concentration. The centrifuge technologies used for each is almost identical. The key operational differences between the two functions are:

- the rotation speed employed

- the throughput, and

- the nature of the concentrated solids product generated.

Dewatering demands more energy than thickening since more water must be removed to achieve the higher solids concentrations. The dewatered product, whose dry solids (DS) content may be as high as 50%, takes the form of a cake: a deformable semi-solid which forms lumps rather than a free-flowing fluid. It can therefore only be conveyed using a conveyor belt, whereas a thickened product retains the fluid properties of the feed and can be pumped.

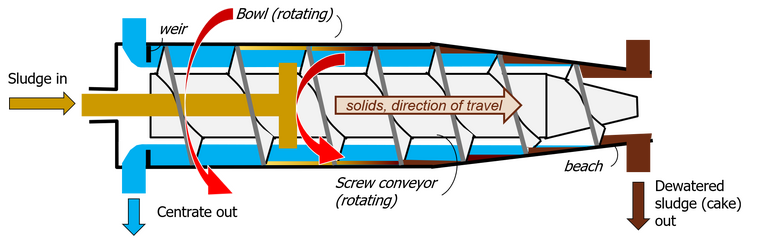

As with thickening, the most common type of centrifuge used for dewatering applications is the solid bowl centrifuge, usually referred to as a decanter or a decanting centrifuge. Its dewatering performance and solids recovery depends on the feed sludge quality and dosing conditions.

Solid bowl decanting centrifuge, Alfa Laval

| Sludge origin | % DS content − Feed | % DS content − Cake | Polymer dose g/kg DS | % solids recovered |

|---|---|---|---|---|

this is a test footnote | ||||

| Primary | 4−8 | 25−50 | 2.5−5 | ≥95 |

| Waste activated sludge (WAS) | 1−2 | 16−25 | 7.5−15 | ≥95 |

| Anaerobically-digested (AD) primary | 2−5 | 25−40 | 4−6 | ≥95 |

| Aerobically-digested WAS | 1−3 | 18−25 | 10−15 | ≥95 |

| Mixed, primary + WAS | 3−5 | 25−35 | 2.5−8 | ≥95 |

| Mixed, AD primary + WAS | 2−4 | 22−35 | 7.5−15 | ≥95 |

The solid bowl centrifuge design can be modified to provide greater dewatering capacity, i.e. a drier solids product, by:

- extending the length of the solids outlet section (referred to as the beach)

- reducing the differential velocity – the difference in velocity between the screw conveyor and the bowl, and

- modifying the screw to provide pressing of the solid cake in the beach area.

The first two of these modifications extend the residence time in the centrifuge. The third provides additional dewatering of the cake.

Solid bowl centrifuges also form the basis of a hybrid dewatering−drying process, where the bowl is adapted to allow it to be heated with a sweep gas. DS concentrations of up to 90% are apparently possible from this process from an unthickened sludge starting material, implying that dewatering and drying of raw sludges can be carried out in a single stage.