Sludge treatment − gravity belt thickening

How gravity belt thickening works

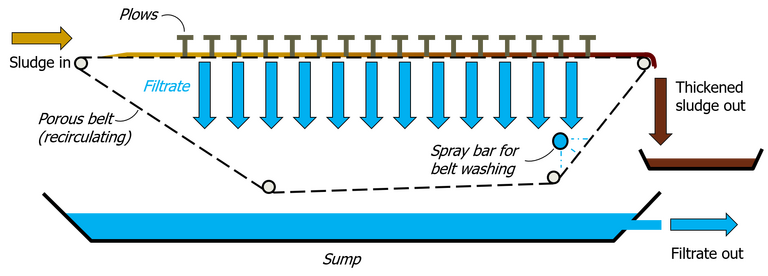

Gravity belt thickening (GBT) increases the sludge solids concentration (i.e. thickens the sludge) by allowing the water (or filtrate) to drain from the sludge under gravity through a permeable medium (a moving belt) on which the sludge sits.

There are two types of belt-based processes for increasing sludge solids concentration. GBT is a low-pressure process which operates by allowing the water to drain from the sludge under gravity. A belt filter press, on the other hand, operates by squeezing water from the sludge under pressure, and achieves a higher dry solids concentration as a result.

In GBT, the sludge solids concentration is increased along the length of a porous belt as water drains through it, the sludge solids forming a layer on the belt surface. The belt is continuously recirculated, as with a classical conveyor belt, and the thickened solids are allowed to fall off the end into a collector vessel – often assisted by a scraper. The filtrate is collected in a sump.

Gravity belt thickener, Alfa Laval

Plows (sometimes called picket fences – not to be confused with picket fence thickeners) are positioned along the belt surface to increase the thickness of the sludge layer and provide a small degree of agitation, both of which encourage the water to drain from the sludge layer through the belt. A spray system is used to clean the belt and prevent the belt pores blocking.

The two key operating parameters for gravity thickening are the sludge hydraulic loading rate (HLR) per unit belt width and the belt speed. The hydraulic loading rate is normally in the range 7−35 m3/h per m width, with an accompanying solids loading rate of 90−1600 kg/(m.h), at belt speeds ranging from 300 to 1200 m/h. Under such conditions, solids capture is 90−98% efficient.

As with all thickening and dewatering operations, the performance is dependent on applying the appropriate polymer dose for sludge conditioning.

| Sludge source | Solids concentration, % Feed | Solids concentration, % Thickened | Polymer dose(kg.tDS-1) |

|---|---|---|---|

| Primary | 4 | 9 | 2−3 |

| Waste activated sludge (WAS) | 3.5 | 7.5 | 4−6 |

| Mixed, primary + WAS | 4.5 | 9 | 4−6 |

| Digested | 5 | 10 | 2−4 |