Thermal sludge conditioning

Introduction to thermal conditioning

Thermal conditioning is used for the pre-treatment of sludge in advance of thickening and dewatering processes.

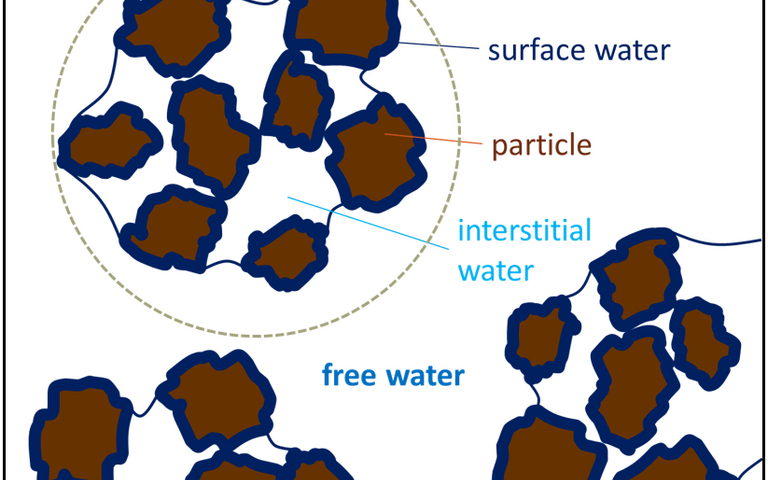

Thermal processes are sometimes used to condition sludges upstream of anaerobic digestion, as well as pre-treating sludge for dewatering. Application of heat disintegrates both the sludge flocs

and the micro-organism cell walls, releasing the bound water (i.e. the water attached to the solids and cells). As a result, the sludge solids are agglomerated, the cell matter largely decomposed and the proportion of the unbound (unattached) free water consequently increased. This results in a conditioned product which is both more dewaterable and more readily biodegraded.

Sludge thermal conditioning employs hydrothermal processes (HTPs). These processes were first implemented for enhancing anaerobic digestion following studies in the 1970s, though heat treatment for enhancing sludge dewaterability dates back to the late 1930s with implementation growing significantly in the 1960s.

Commercial HTP processes include the CAMBI™ process and Veolia’s Exelys™ technology. These processes operate at temperatures of up to 200 °C and pressures up to 10 bar, the pressure being applied to maintain water in its liquid state. Thermochemical treatment under these conditions has been shown to significantly increase sludge dewaterability, by between 60 and 80% in the case of the CAMBI process.

The CAMBI hydrothermal sludge treatment process

The primary disadvantage of thermal conditioning is the requirement of boilers to provide the thermal energy. It is therefore only generally viable if combined with anaerobic digestion (AD), which generates methane as a product. The methane can then be used to provide heat and electrical energy using combined heat and power (CHP) engines.

Since dewatering is not required upstream of AD, thermal conditioning is generally implemented upstream of AD, ostensibly to improve AD efficiency in terms of conversion of the organic carbon to methane. However, it has been demonstrated that thermal pre-treatment also significantly increases the dewaterability of the solid stream (digestate) from the AD process. Solids contents of more than 40% have been reported for centrifuge cakes generated from a digestate from an HTP-pre-treated AD process, compared with ~20% for an AD digestate generated without thermal pretreatment (Barber et al, 2018).