Sludge drying beds and lagoons

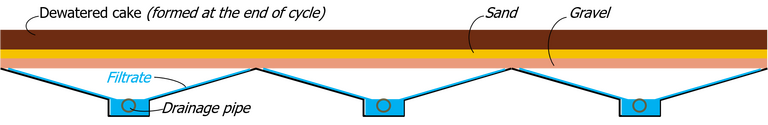

Sludge drying beds provide sludge dewatering by allowing the liquid to both drain under gravity through a permeable medium on which the sludge sits, and to evaporate under ambient conditions. Lagoons provide dewatering through evaporation alone.

Sludge drying beds

Sludge drying beds, along with lagoon technology, represent the simplest of the dewatering technologies. They are typically employed directly for stabilised, unthickened solids from extended aeration and digested solids.

Drying beds are uncomplicated in design and operation, since they involve simply spreading the sludge as a thin (up to 300 mm) layer over a porous bed of sand and gravel. The water is then allowed to drain through the bed and into a network of embedded drainage pipes to allow it to be collected. Further water removal is provided by evaporation from the sludge surface.

The degree of dewatering attainable depends on the drying duration and, if the bed is uncovered, the weather conditions. Once sufficiently dewatered, which takes 10−15 days and is evident from the appearance of cracks and a dark brown surface, the solids (30−40% DS or dry solids) are mechanically removed. Removal is normally using a front end loader or specialist mechanical sludge removal equipment.

While most drying beds are uncovered and their performance therefore subject to the local meteorological conditions, water evaporation rates can be increased by housing the beds within a glass structure (a greenhouse). This modification is usually termed a solar drying bed and is sometimes employed in warmer climates.

Although low in energy and operating costs, the large footprint incurred by drying beds limits their use to applications where land availability is not constraining. Solids loading rate values for drying beds are around 100 times lower than those for a gravity thickener.

| Digested sludge origin | Solids loading rate − kgDS/(m2.y) |

|---|---|

| Primary | 120−150 |

| Primary + trickling filter humus | 90−120 |

| Primary + waste activated sludge | 60−100 |

Lagoons

A sludge-drying lagoon can provide a dewatering and end disposal route for digested sludge in regions where land availability is not constraining, potential environmental impact and risk to human health is limited, and a low-cost solution is required. It is similar to a drying bed in demanding large land areas and labour-intensive mechanical removal of the dewatered solids, but is simpler in construction since no drainage of the filtrate is required.

A lagoon comprises a shallow reservoir with a sealed base to prevent ingress of the sludge water into groundwater, aquifers or other environmental water bodies. The lagoon is filled with sludge and the solids allowed to settle. Over the drying/dewatering operational cycle, which is in the region of several months, water is lost through evaporation while the solids form a thick layer at the base of the lagoon, stabilised by anaerobic biological processes.

Usually, a supernatant water layer of more than 0.5 m is maintained over the digesting sludge layer. This layer allows the oxidation of odorous compounds generated by and released from the sludge layer during anaerobic digestion. Once the dewatered sludge reaches the desired solids concentration of 25−30% DS, the dried sludge is removed.

A typical operational cycle of a sludge-drying lagoon is usually more than one year depending on the local climate. It is considerably longer than the corresponding period of a drying bed, where most of the water is lost through draining.