Designing anaerobic digestion systems for sludge treatment

Designing anaerobic digestion systems

Anaerobic digestion (AD) systems can be designed as:

- a single or multiple tank process,

- a stirred or unstirred system, and

- operational at either moderate (mesophilic) or elevated (thermophilic) temperatures.

There are also various reactor configurations, including a continuous stirred tank reactor (CSTR) and upflow anaerobic sludge blanket (UASB). The sludge can be fed either as a slurry (‘wet’ mode) or as granules or a powder (‘dry’ mode).

The tanks can be either cylindrical or egg-shaped. Egg-shaped reactors provide superior hydraulics, which reduces the required mixing intensity.

In a single tank process, all steps of the biochemical degradation mechanism are carried out in one reactor. For a multi-tank process, each reactor is specific to one or more of the individual steps of the degradation mechanism.

The multi-tank approach to anaerobic digestion allows better control of the process biology, most specifically via the pH. The optimum pH range for acidogenesis and acetogenesis is normally around 5.5−6.5: within this pH range the organic acid-producing micro-organisms grow and reproduce more rapidly than the methanogenic bacteria. Methanogenesis, on the other hand, operates most effectively within a pH range of 7.8−8.2.

Operation in a single tank demands careful control to ensure that the pH is kept within a range where all the biochemical steps can take place simultaneously. This implies an optimum pH range of 6.8−7.2, though the process can tolerate a range of 6.5−8.0.

Unstirred tanks are simpler in design and operation but are limited to low loading rates and long hydraulic retention times (HRTs). As a result, the tanks in unstirred systems are larger than those used for stirred systems. Conversely, stirred tanks (i.e. tanks employing mixing) are normally favoured – because of their lower footprint – for large sludge flows in particular.

AD processes employing mixing comprise two stages:

- a primary digester which is completely mixed, followed by

- a secondary digester where separation of the digested sludge and supernatant takes place.

Biogas generated from both stages is combined to form the product gas stream.

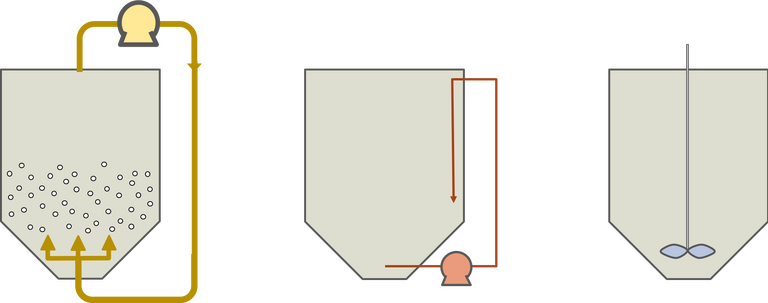

Mixing can take place by recirculating the pressurised biogas through diffusers at the tank base, recirculating the sludge (i.e. jet mixing) or by mechanical mixing with impellars.

Thermophilic operation (49−57°C optimum range) demands more heating than mesophilic operation (30−39°C optimum range), but the biochemistry takes place more rapidly. This means the HRT is lower and the tanks smaller.