Challenges to anaerobic digestion in sludge treatment

Overview of AD challenges

There are two widely recognised challenges to anaerobic digestion (AD) operation:

- foaming, and

- over-acidification.

These two factors are often inter-related since they both relate largely to control of the microbiology through balancing of the organic and nutrient loads. They also both lead to a decrease in the methane yield, which can then be diagnosed through monitoring the biogas methane and carbon dioxide concentrations.

Challenges are often associated with insufficient process control. Specifically, they arise from an imbalance of the reaction rates for those microbial steps promoted by acidic conditions (acidogenesis and acetogenesis) and those steps requiring neutral/basic conditions (methanogenesis).

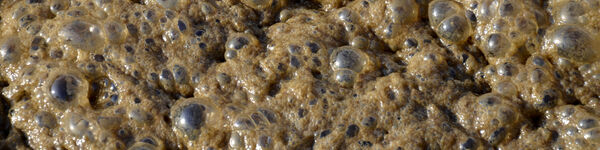

Foaming

Foaming is perhaps the most common challenge in AD operation. It can last from a few days to several weeks and can cause a number of operational issues including:

- reduced biogas production (by up to 40%)

- damage to process equipment (compressors, pumps, etc)

- obstruction of valves (and specifically the pressure relief valves)

- rupture of digester tanks or tank covers.

The rupture of the vessel or cover itself is an extreme example and can lead to release of hazardous material and demand extensive repairs.

Foaming is often associated with high loading rates, increasing the carbon dioxide−methane ratio, along with high surfactant levels and/or the presence of filamentous bacteria such as nocardia. Both surfactant chemicals and filamentous bacteria can cause emulsification of the foam bubbles, trapping the gas inside the reactor instead of it being released to the biogas collection vessel.

Excessive amounts of foam cause damage if they are able to enter the gas compressor line and form a solid deposit on the pressure relief valve.

While there are general rules of thumb for the prevention of foaming, it is not a well-understood phenomenon. Its build-up can be monitored visibly through a viewing port into the reactor or through the installation of a specialist sensor.

Foaming is most easily suppressed through the addition of chemicals. However, if its cause is primarily biological in nature, then the application of antifoamants does not provide a sustainable solution. Instead, it is necessary to adjust the operating conditions to prevent the accumulation of the filamentous bacteria causing the foam.

Over-acidification

Over-acidification becomes an issue in single-tank systems where control of pH at around neutral levels is required to sustain the biochemical reaction. Anaerobic digestion relies on two microbiological processes proceeding simultaneously to:

- (i) break down the organic matter in the feed to simple, small molecules (through acidogenesis and acetogenesis), and

- (ii) convert these to methane and carbon dioxide (by methanogenesis).

The optimal pH ranges differ between these two steps, the first being favoured at low pH values and the second at higher values. If, during the first step, the pH drops substantially below 6.5, the methanogenic organisms cannot survive and methane is no longer produced. The process is then described as stuck and, in extreme conditions, the process can take several months to be restored to fully operational levels.

As with foaming, over-acidification is often associated with insufficient control and specifically fluctuating and/or excessive loading of the organic substrate. It may also be linked to low levels of nutrients (macronutrients such as nitrate and phosphate as well as micronutrients like magnesium and calcium) or poor temperature control.

The balance of organic matter substrate − i.e. the volatile fatty acid (VFA) to inorganic carbon (IC) − is often used as an indicator of over-acidification, since the IC is made up largely of bicarbonate. Bicarbonate is a chemical buffer − it maintains the pH at neutral levels, the optimum pH range for a single-tank AD process. High VFA:IC ratios, associated with unsustainably high organic loads, may therefore cause over-acidification.

There is some evidence, however, that the ratio of VFA to macronutrients (such as phosphate) and micronutrients (such as magnesium) may provide a better indicator of over-acidification than the VFA:IC ratio.