Belt filter presses for sludge dewatering

How belt filter presses work

A belt filter press (BFP) provides sludge dewatering by pressing the sludge to force the water through a permeable medium. The process produces a cake (the dewatered product) having a dry solids (DS) content of 30% or more in the case of primary sludge. This is to be distinguished from the lower-energy gravity belt thickener process which achieves a maximum DS content of ~10%.

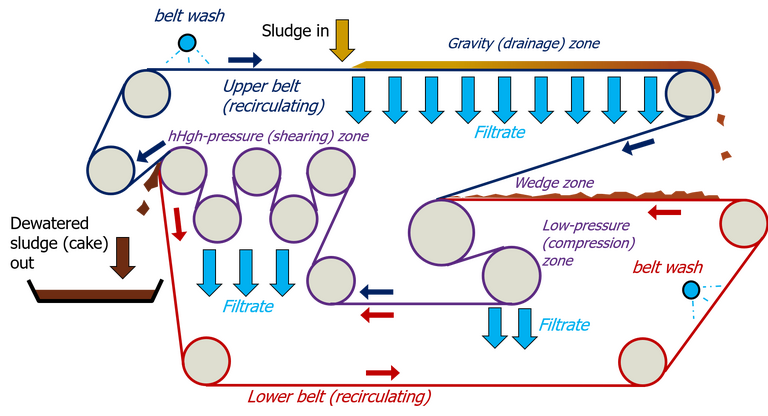

A BFP combines drainage and mechanical pressure sequentially to remove water. The equipment normally comprises 2−3 recirculating belts, with two belts combining at some point to compress the sludge and squeeze water from it.

The conditioned sludge feed is first conveyed along a gravity drainage section of one of the porous belts, as with a gravity belt thickener. It is then subject to pressure as it is passed between two recirculating belts, forming a wedge zone at the inlet, which travel over a roller. This squeezing action from the two belts in this pressure zone releases more water.

Many belt filter press technologies contain a second pressure zone comprising a series of rollers through which the two belts pass with the sludge solids retained between them. The rollers in this high pressure zone apply tensioning (i.e. stretching) to the belts, exerting both shearing and compressive forces on the sludge which further release more water.

Some BFP technologies are based on a three-belt system, where the gravity belt is independent of the two pressurising belts. This allows the recirculation rate for the thickening operation to be separately adjusted from the dewatering operation.

In common with the gravity belt thickener, the belts are subject to cleaning with water spray to limit the plugging of the filter belt pores. The waste washwater is combined with the filtrate.

The overall performance of the BFP is dependent on the feed sludge source and characteristics and the dosing conditions. As with all other thickening and dewatering technologies, primary sludges – both raw and anaerobically digested – are more readily filtered than waste activated sludge (WAS).

Belt filter press Alfa Laval

| Sludge origin | % DS content − Feed | % DS content − Cake / Typical | % DS content − Cake / Range | Loading/m belt width − liquid m3/h | Loading/m belt width − solids kg/h | Polymer dose − g/kg DS |

|---|---|---|---|---|---|---|

| Primary | 4−8 | 30 | 26-35 | 14−38 | 1130−1590 | 1.5−2.5 |

| Waste activated sludge (WAS) | 1−2 | 16 | 12-20 | 11−23 | 180−340 | 5−10 |

| Sequencing batch reactor (SBR) | 1−2 | 16 | 12-19 | 11−22 | 250−360 | 5−7.5 |

| Membrane bioreactor (MBR) | 1−2 | 15 | 11-18 | 16−25 | 230−320 | 5.5−10 |

| Anaerobically-digested (AD) primary | 2−5 | 28 | 24-35 | 14−37 | 680−910 | 2−5 |

| Anaerobically-digested WAS | 2−3 | 20 | 13-23 | 6.6−20 | 230−410 | 4−10 |

| Mixed, primary + WAS | 3−5 | 23 | 15-25 | 9.0−27 | 340−820 | 3−5.5 |

| Mixed, AD primary + WAS | 2−4 | 24 | 15-28 | 9.0−27 | 320−540 | 4−8.5 |