Pretty intense: the intensification of sewage sludge processes

Simon Judd

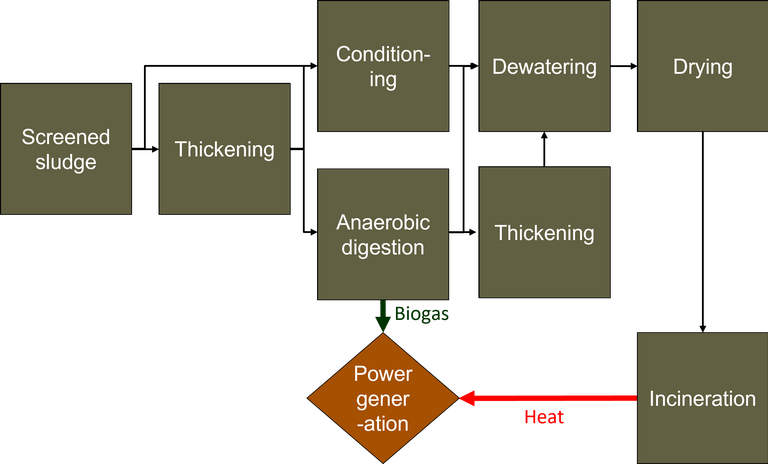

Sludge volume is reduced − and solids concentration increased − by removing water. Digestion converts organic matter to biogas, and in doing so reduces the amount of organic solids.

Reducing waste volumes makes sense but − how far should you go? Simon Judd, co-owner of SludgeProcessing.com, discusses the intensification options in sludge processing.

What is 'sludge process intensification'?

Intensification can, it seems, be interpreted in many ways. As far as sludge treatment processes are concerned (see below), the most obvious one is increasing the solids concentration through consolidation. There are a number of different ways of achieving this depending on the technology type. If it’s a centrifuge, then enhanced consolidation is through using higher rotation speeds. For a filter, belt filter or screw press, it’s by increasing the pressure, and for simple gravity drainage there’s the option of employing electrokinetics.

In fact, it’s almost always possible to extract a bit more water from the sludge, but there are diminishing returns from doing so: beyond some point the additional energy applied is greater than the possible value derived from a more consolidated product. Which then begs the question: where is the line ultimately drawn? What governs the limit to the amount of additional energy that can usefully be applied to reducing the sludge water content?

The answer to this sort of question is nearly always the same. And that answer is: it depends. In this instance, the most important factor is the intended goal, which is normally one or more of the following:

- reduce its volume to reduce the cost of its transport/conveyancing

- render it reusable for application to land, which generally means reducing its pathogen content and putrescence, and/or

- render it more readily treatable by anaerobic digestion, whereby the organic carbon is converted to methane by methanogenesis and the sludge both reduced in volume and made innocuous.

Consolidation (thickening/dewatering)

For further consolidation to be of value, it must incur a lower cost − or carbon/environmental footprint − than that associated with 1−3 above.

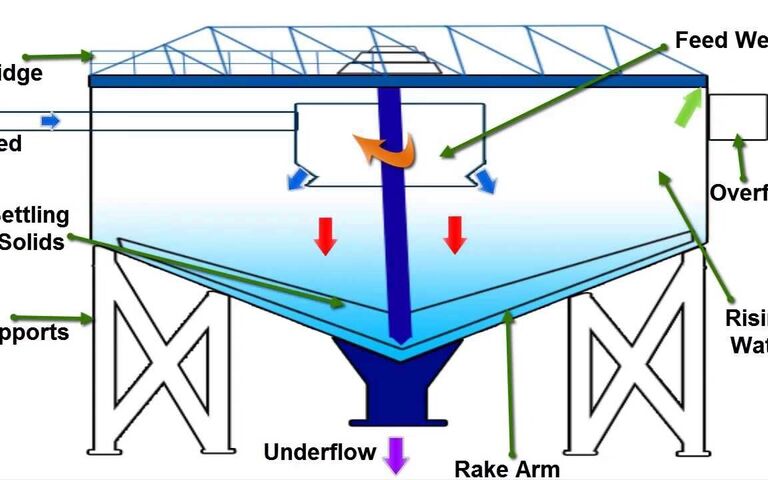

Thickening requires the consolidated sludge to remain pumpable. This demands a minimum water content, such that there is nothing to be gained by attaining an overly high solids content. However, as with any consolidation process, there may be an advantage to be gained by optimising the flocculation chemistry to reduce the energy and/or time required for consolidation.

Dewatering aims to remove as much water as possible. Various intensification methods have been implemented or explored for the individual technologies.

Electro-osmotic dewatering represents an enhancement of a belt filter press. It employs high voltages to encourage the water to drain from the sludge cake by the action of an electrokinetic force. However, if the sludge has a high electrical conductivity this then leads to expending electrical energy on electrolysis, generating hydrogen and chlorine.

The dewatering action of a filter press can be extended using a diaphram or membrane which is inflated towards the end of the cycle to squeeze out additional water from the sludge cake. This represents an elegant means of further compressing the cake once the mechanical compression provided by the filter plates is complete. The use of membranes adds to the cost, since they must be periodically replaced, as well as to the process complexity. However, the supplementary membrane-based compression is relatively fast, reducing the cycle time and so increasing the filter press capacity.

In all cases, generating a dryer dewatered cake:

- decreases the supplementary energy required to produce a granular or powdered product by thermal drying, or else

- decreases the weight and volume for haulage.

Anaerobic digestion

Intensification of the anaerobic treatment is generally taken to mean increasing the biochemical conversion of organic carbon to methane and, in doing so, reducing the residual solids. It can be expressed in terms of the overall energy balance in kWh recovered per kg of organic carbon (expressed as kg COD or BOD).

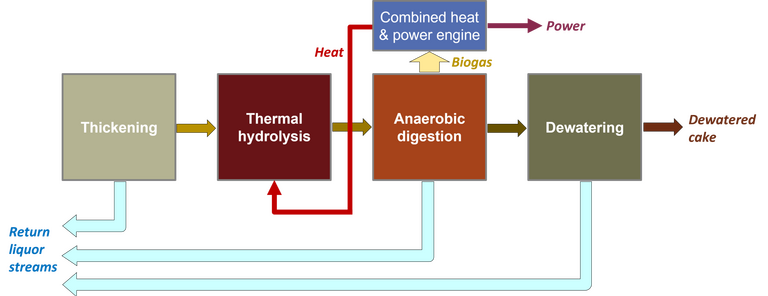

Partial thermal hydrolysis of the sludge upstream of the AD process can increase both the yield of methane generated by digestion and the product dewaterability, and several commercial technologies have been developed for this. The energy demanded by the thermal hydrolysis step (at a temperature generally between 90 and 180 °C) is more than made up for by the additional methane generated through the enhanced conversion coupled with the reduced solids content of the product. As with the filter press, the energy-related cost benefit of the intensification has to be weighed against the cost of the additional process step.

In summary ...

There are a number of sludge processing intensification methods already established for enhancing solids consolidation or biogas generation. The benefit gained is most often quantified as energy saving, and this has to be offset against any required supplementary energy input and/or capital investment (or embedded carbon, if based on life cycle analysis).

Other increasingly important aspects of sludge processing are affected by intensification. Foremost amongst these is the fate of macro nutrients (nitrate and phosphate) and problematic/onerous biorefractory micropollutants including certain pharmaceutical and perfluorinated chemicals (such as PFAS). If intensification can improve either the recovery, retention or elimination of some or all of these materials then this subsequent additional benefit may ultimately exceed that provided by the more conventional measure based on energy.

There are already commercial processes for phosphate (P) recovery. Ammonia recovery, on the other hand, does not currently appear to be economically viable. There is instead increased focus on its removal using lower energy technologies, most notably with Anammox bacteria (the 'nitrite shunt' process). Recovery of any species is nonetheless favoured at higher concentrations – which is why P recovery is generally only economical for the sludge return liquors (shown in the above figure). In this regard, intensification may offer a benefit if the process increases solubilisation of a chemical recoverable from the aqueous phase, as with phosphate.

As for the micropollutants, there is naturally a significant research focus on both the partitioning of these compounds between the solid and liquid phases in sludge and their degradation pathways (biochemical, chemical and/or thermal). However, for some of these chemicals − most notably PFAS − options for mitigation appear to be limited and/or unpalatable. Incineration at elevated temperatures (intensified thermal oxidation) is able to oxidise PFAS, but this process is not universally popular.

Sludge intensification processes generally offer clear benefits from an energetic and waste reduction perspective. Further benefits, or otherwise, relating to nutrient recovery and/or micropollutant abatement influence their more widespread implementation.