Biological sludge treatment − overall solution

Biological sludge treatment − overall solution

-

Thickening, dewatering & drying

- Thickening

-

Dewatering

- Belt filter presses

- Screw presses

-

Drying

- Rotary drum dryers

- Pelletizers

-

Thermochemical processes

-

Thermal destruction - non-oxidative

- Pyrolysis

-

Thermal destruction - non-oxidative

- Municipal Sludge

Case study description

Full sludge treatment of a municipal wastewater treatment plant, from 98.5% to 0% water content.

The solution consists of dewatering raw sludge at ~98.5% water content via the Benenv screw press model MDS404, with capacity of 680 kg dewatered sludge per hour. The sludge cake has a moisture content ~80% before entering the next phase, which is the deep dewatering belt press model BNSD-1.0 with capacity of 1000 kg/hour. The belt press provides further reduction in the sludge cake moisture, from ~80% down to ~58%. The sludge cake following dewatering comprises flakes, due to a granulator installed at its inlet.

A conveyor transfers the sludge cake to the super rotary sludge dryer (BRD-500 model), with an evaporation capacity of 500 kg water per hour. The dying process consists of blowing hot air at a temperature of 140~160oC through the agitated flakes. An internal disintegrating shaft breaks the flakes into small granules of 1~3mm size. The dried sludge has a moisture of 15~18%.

An interlocked sludge carbonizer (model BMT-300), based on sealed pyrolysis with heat recovery, provides a fully carbonized product with zero moisture. The final product is used as filler in the construction industry, and as soil enhancer.

The sealed unit means that there are no gaseous emissions from the carbonizer. The vapours are directed back to the dryer furnace, with a sidestream passing through scrubbers before discharge to the atmosphere.

The emissions are 100% safe, and are below the national limits.

Company's role in the project

BOT (Build Operate Transfer)

Other directory listings from Benenv…

Multi-disk screw press for thickening and dewatering

Sludge treatment equipment supply

The Wave Separator for thickening and dewatering

Pharmaceutical sludge dewatering

Drying of pickling sludge

Sludge carbonization − pig manure

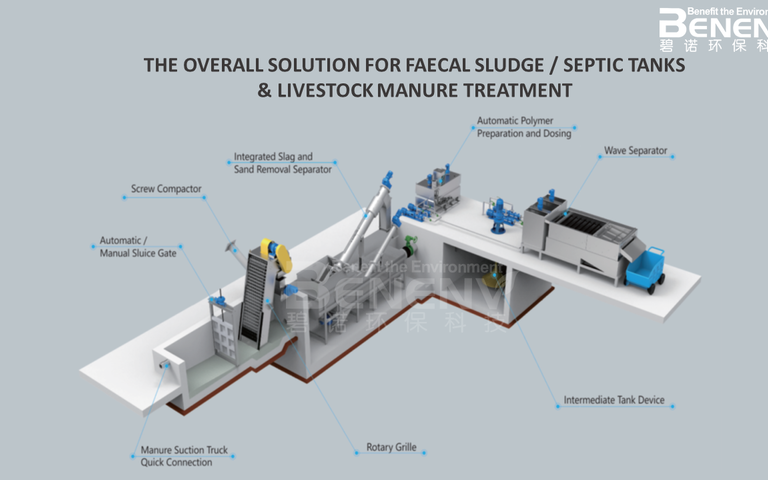

Faecal sludge treatment solution

About this page

This page was last updated on 16 November 2021

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. SludgeProcessing.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.