UK water net zero carbon: the true benefit of biosolids to land

Andrew McLeod, Bioresources Process Engineer, and Amanda Lake, Regional Solutions Lead Wastewater Europe, Jacobs

1. Biosolids management and the circular economy

In June 2019, the UK introduced its 2050 net zero target amendment to the Climate Change Act (2008), becoming the first major economy to pass net zero emissions legislation. A year on, the Committee on Climate Change’s June 2020 progress report has revealed that the UK is already far off-course, with just 1 of 25 critical policies delivered [1]. The CCC report provides specific recommendations for government departments and highlights the need for Water Industry regulator Ofwat to include decarbonisation as one of its core principles in light of the water industry’s goal of achieving Net Zero by 2030.

As the fourth most energy intensive industry in the UK, Water Companies have recognised the need for climate action, and are making progress in developing their net zero plan. Some, such as Severn Trent, have committed to developing Science Based Targets. With the scope and scale for carbon emissions to be addressed across the entire urban water cycle, the industry has a key role in helping the UK achieving its 2050 target and Paris commitments. In their recent open letter [2] to the industry, the Government, Environment Agency, Drinking Water Inspectorate, Ofwat and the Consumer Council for Water challenged Water Companies to consider their role, to increase ambition and to implement nature-based solutions and net zero ideas to support the post-Covid green recovery.

The recycling of biosolids to land is one of the most important ways Water and Sewerage Companies (WaSCs) currently contribute to the circular economy, providing a sustainable source of crop nutrients and avoiding disposal to landfill. Importantly, recycling biosolids to land also reduces carbon emissions by substituting for carbon-intensive manufactured fertiliser and sequestering stable organic carbon within the soil. Although UK WaSCs are already returning around 90% of biosolids to land, the industry does not currently quantify the environmental and carbon benefits of this recycling and is yet to consider these in its net zero road map.

Reducing greenhouse gas emissions must be the priority in our rapidly warming planet. However, we also see the importance in recognising the circular benefits of biosolids to land today. These must be better understood and able to be well communicated − particularly given increasing concerns over the impacts of emerging contaminants, including microplastics and per- and polyfluoroalkyl (PFAS) substances in wastewater and biosolids. Raising industry ambition to consider the full extent of Scope 3 emissions [3] is important and part of this should be understanding wider carbon impacts.

By quantifying the carbon benefits of biosolids to land, the UK industry has a key opportunity to support a fair and balanced narrative around biosolids, to better recognise benefits and to develop a future-looking framework for sustainable, circular resource use. Here we discuss the importance of action to do this today.

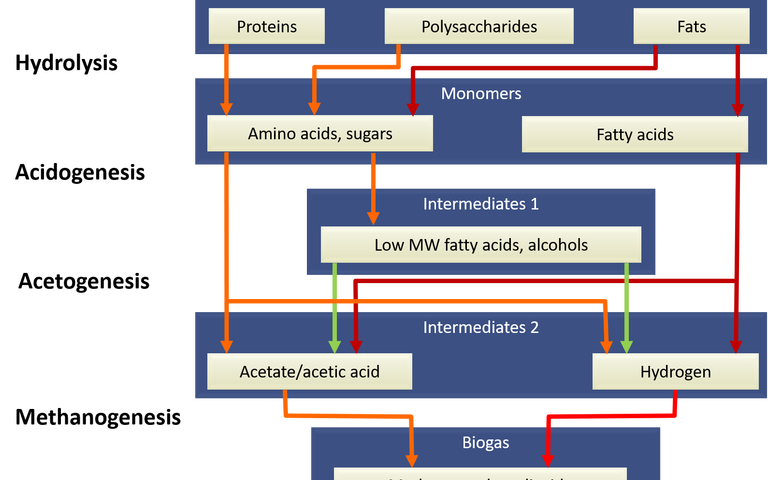

2. The story of biosolids and carbon

Soils have a capacity to retain organic carbon that is applied to them, which would otherwise be rapidly transferred to the atmosphere as CO2. Where carbon transfer to soils results in net additional transfer of carbon from atmospheric CO2, this can contribute to slowing or even reversing global heating and climate crisis [4]. An estimated 4−5 GT CO2 per year [5] may be sequestered globally within depleted soils with implementation of best management practices – this being equivalent to some 12% of global 2018 fossil fuel CO2 emissions [6].

Soil organic carbon is depleted in many cases where historic farming practices have prioritised short-term crop yield over soil health and good soil organic carbon management. The IPCC reports that conventional tillage degrades soils up to 100 times quicker than soil can naturally form. While crop yields have increased 200% since the 1960s, this is concurrent with an 800% increase in manufactured N fertiliser use. This illustrates a worrying feedback loop, where poorly managed soils low in organic carbon require increasingly greater input of manufactured, carbon intensive, fertilisers to maintain crop yield.

Increased use of manures that are rich in organic matter, such as biosolids, is recognised as a key solution to build-up of soil organic carbon to restore soil health and provide carbon sequestration to reduce global heating. The globally recognised compendium of viable climate solutions for today, Project Drawdown, lists the conversion of organic waste into soil carbon through regenerative agriculture in its top 20 solutions we have today to limit global heating to 1.5 ⁰C [7]. Nutrient management is also in the top 20 solutions, with delivery of nitrogen to the right place at the right time to maximise efficiency of use. Biosolids achieve this as a slow release of nitrogen that accelerates with rising spring-time temperatures in alignment with crop growth.

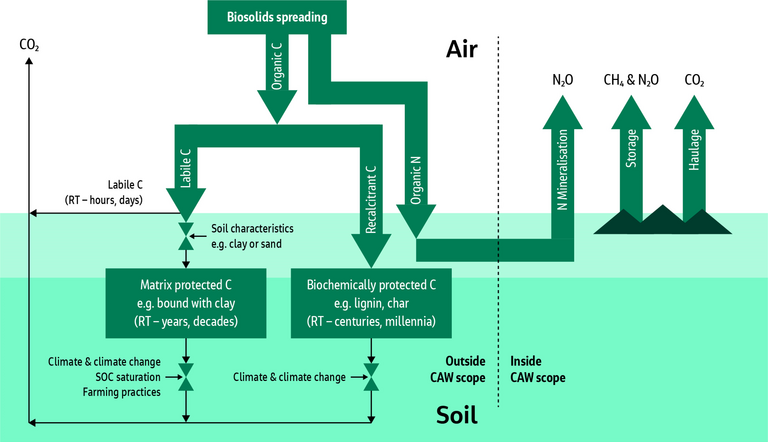

This, coupled with the lability of biosolid organic matter, can reduce nutrient leaching and diffuse nutrient pollution – contributing to the Water Industry National Environment Programme’s required environmental outcomes for AMP 7. We can estimate the scale of potential carbon benefits of recycling biosolids to land in terms of the carbon sequestration in soil and the carbon savings from avoided fertiliser usage (Figure 1). Whilst the system is highly complex, we consider a high-level assessment of the carbon benefits of biosolids recycling to land below.

3. An industry approach to quantify carbon impacts

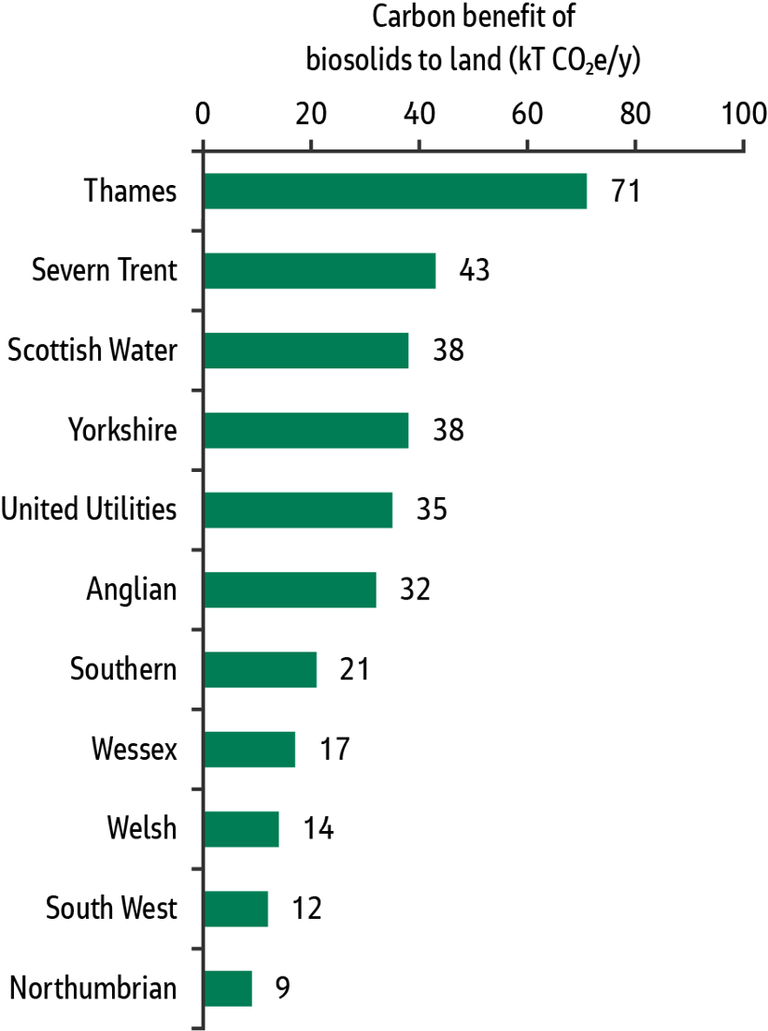

Globally, existing industry approaches [8] to assess carbon benefits of biosolids to land have allowed utilities to assess the carbon emissions and reduction potential of various biosolids management options [9], which have been used to evaluate carbon credits [10]. An approach such as this would provide valuable high-level understanding of greenhouse gas emissions from biosolids recycling in the UK. We have applied this methodology to estimate the carbon benefits to reported biosolids production figures made available for the industry in England, Wales and Scotland (some 930M tonnes of dry solids per year [11]) and considered the carbon sequestration and fertiliser offset benefits of biosolids recycling (Figure 2). We can compare these carbon benefits to the reported industry baseline emission of approximately 2.65 MtCO2 [12] as reported Scope 1, 2 and 3 emissions. This figure is indicative since full annual operational carbon emissions are not publicly reported; we would welcome improved visibility of the figures given the very interesting story they have to tell citizens about carbon and the water industry.

Our assessment shows significant carbon benefits in considering the wider system carbon and we calculate potential carbon benefits to industry which could equate to 10−20% of the current operational carbon footprint, based on assumptions discussed further below. In terms of contributions, carbon sequestration is most significant, although this is also likely to be most variable (Figure 3) – as shown in work by UKWIR, where biosolids spread on different soils over 20 years retained 35−60% of the organic carbon applied to them [13]. The offset of manufactured fertilisers, particularly nitrogen, is limited by the low crop availability of nitrogen in biosolids (10−20% of total N) and a biosolids application rate restricted to 250 kg/ha of total N. This means UK farmers will continue to ‘top-up’ with manufactured nitrogen.

Emissions for haulage and spreading are relatively small, but will depend on haulage radius (50 km assumed). Fugitive release of methane and nitrous oxide during field storage and from mineralisation of nitrogen post-spreading represent the largest positive emissions from biosolids to land but remain less than half of the carbon benefit provided through carbon sequestration.

![Figure 3. Relative contributions to emissions from biosolids storage and spreading (GHGs), fuel use for haulage and spreading, fertiliser carbon benefit and carbon sequestration [14]](https://www.sludgeprocessing.com/transforms/images/Features/57037/feature_net-zero-carbon_fig-3-1a7f090991.png)

Our calculation is high level and requires development for the UK industry but shows the benefits of a Tier 2 UK country level model to provide quantification of carbon impacts of biosolids to land. It is important to highlight the system complexity: carbon effects are variable and largely depend on the finite capacity of specific soils to protect and retain the more ‘labile’ (less stable) fraction of organic carbon for a meaningful amount of time (as shown in Figure 1). The initial proportions of labile and ‘recalcitrant’ (more stable) carbon in the biosolids input will depend upon the treatment processes used. The extent of manufactured fertilisers offsetting will depend on the crop availability of nutrients, crop nutrient requirement and biosolids application rate. An industry wide model will allow the scale of carbon benefits to be assessed; more detailed methods are likely to be useful to provide accuracy and to develop further emissions mitigation approaches with farmers in catchments.

4. Biosolids to land in a time of climate crisis

Over the next decade, UK water utilities will recycle around 10 million dry tonnes of biosolids to land, equal to around 3.3 million tonnes of organic carbon with a carbon benefit of up to 12 million tonnes CO2 [15]. Around 440,000 tonnes of phosphate and a similar amount of nitrogen will also be recycled back to land [16] for agricultural benefit. Improved understanding of the industry’s biosolids to land carbon balance will support the holistic emissions quantification and mitigation required.

Our initial work concludes:

- Quantify carbon benefits. To accurately start to tell the biosolids carbon story, there needs to be industry-wide understanding and quantification of both emissions and carbon benefits of the current practice, initially with a Tier 2 level tool. This could be tailored through the Biosolids Assurance Scheme, in line with incoming revision of the Environmental Permitting Regulations. An initial tool should be developed rapidly. Output carbon assessment could be incorporated into the existing industry operational Carbon Accounting Workbook but must not detract from emissions reduction (for example Scope 1 process emissions).

- Data collection and analysis. Water Companies should collate empirical data on carbon sequestration and wider benefits from biosolids to land and identify data gaps for further collaborative research and more detailed analysis methods to better understand the role they can play in sustainable agriculture. This should identify how existing routine sampling can be adapted to fill gaps.

- Include carbon. Ofwat must incorporate carbon into future price reviews and should incentivise the quantification and sharing of industry carbon datasets to improve on industry, customer, farmer and wider supply chain carbon collaboration and to realise the necessary innovation to achieve net zero. The UK’s regulatory landscape around biosolids to land remains dynamic and must also be considered:

- Environmental Permitting Regulations. Previous spreading of biosolids on land up to a phosphate (P) index of 4, without direct EA oversight, could become difficult to justify to the EA. Restriction to land up to P index 2 will impact haulage if land closest to works has historically been most heavily applied. A holistic evaluation of biosolids to land emissions will help to evaluate and offset any increased fuel use emissions within the broader biosolids carbon accounting.

- New Agricultural Bill 2019−2021. Financial support will be given to farmers for practices benefiting soil health and the environment. Biosolids application to land may fit into ‘Tier 1’ payments of Environmental Land Management schemes in development (from 2024), though this remains unclear. A fair depiction of biosolids that includes their carbon, nutrient and soil benefits is key: inclusion in the schemes may incentivise biosolids use and other net zero approaches by farmers who the industry work with whilst exclusion may constrain biosolids in favour of other organic materials and practices that prohibit biosolids application such as organic farming or no-till.

- Emerging treatment technologies. Disruption of biosolids to land or the ability to recover further energy from sludge may drive uptake of new thermal conversion technologies in the future. Evaluation of these technologies, such as gasification and pyrolysis, will call for even more holistic understanding of carbon, e.g. impacts of reduced biosolids to land and potential for beneficial biochar use.

5. A road map to net zero: the benefits of biosolids to land

Agricultural practices which build soil health increase carbon storage and offer significant wider economic and environmental benefits – such as increased crop yields and improved water quality. Better understanding and assessing the benefits of biosolids to land through more collaborative, multidisciplinary and cross sector approaches is required. This will allow assessment of maximum carbon benefits across Water Company value chains now and in the future, providing key understanding and focus for successful Climate Action towards net zero by 2030.