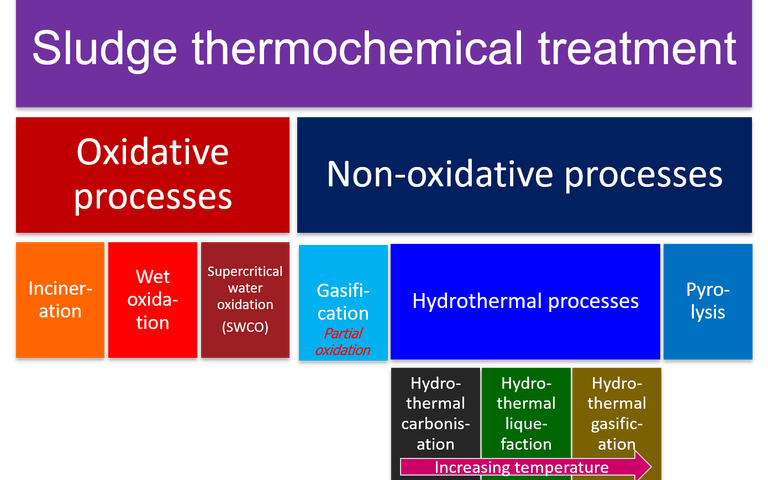

Sludge thermochemical treatment

An introduction to sludge thermochemical treatment methods

Your web browser is out of date.

Update your browser for better security, speed and to get the best experience on this website.

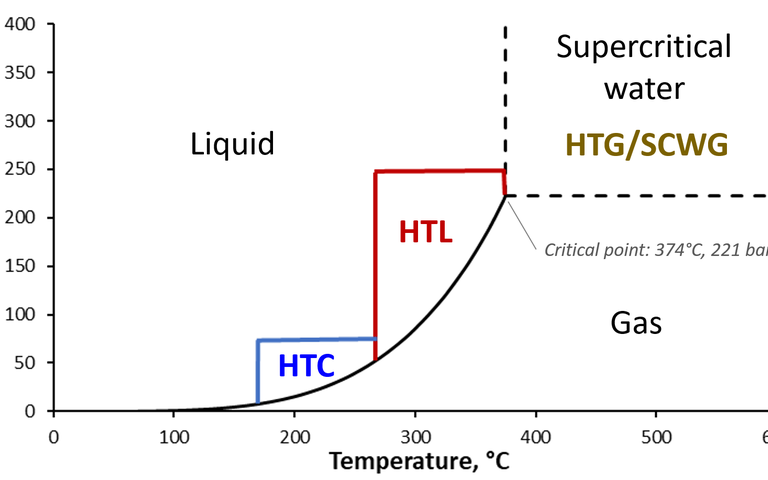

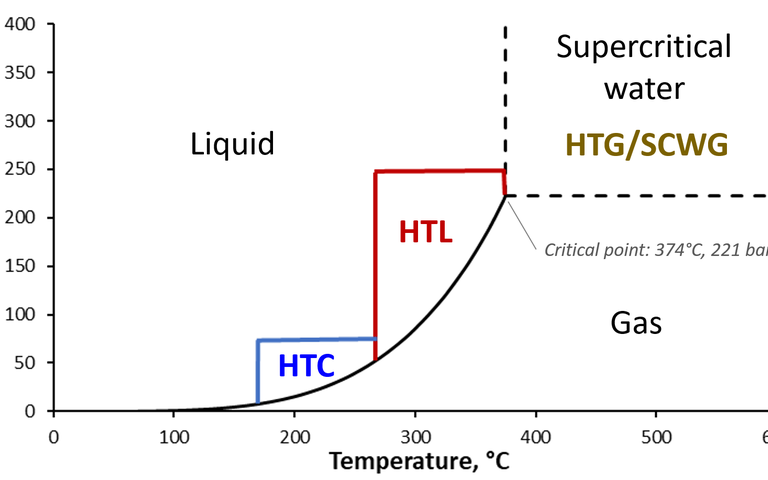

Hydrothermal carbonisation (HTC) converts sludge predominantly into a carbon-rich hydrochar solid product. The process is conducted at temperatures generally between 180 and 300 °C, with corresponding pressures above 10−88 bar to ensure that the water is maintained in the liquid state. Reaction times ranging between 0.1 and 4h have been employed. The precise conditions of temperature, pressure and time selected depend both on the feed sludge quality and the target yield and characteristics of the hydrochar product.

An introduction to sludge thermochemical treatment methods

Thermochemical methods are used for either degrading the sludge solids or pre-treating sludge upstream of anaerobic digestion

Various reactor configurations exist for sludge thermochemical treatment which vary in design, operation and application

An introduction to non-oxidative sludge thermochemical treatment methods

Hydrothermal sludge treatment employs elevated temperatures and pressures in wet conditions and in the absence of oxygen

A video to demonstrate HTCycle HTC technology.

Gasification is conversion at very high temperatures in a partial reducing atmosphere to generate a syngas product

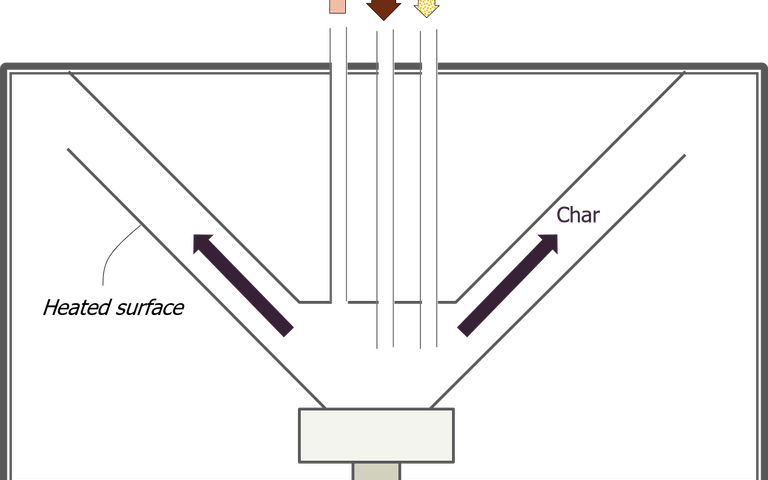

Pyrolysis is the decomposition of organics at temperatures of 300-1300 °C in the absence of oxygen at atmospheric pressure

Hydrothermal processes employ elevated temperatures and pressures in wet conditions and in the absence of oxygen

Hydrothermal liquefaction of sewage sludge takes place at temperatures of 250–400 °C and pressures above 40 bar

Hydrothermal gasification converts sludge to a hydrogen and/or methane-rich gas stream at temperatures up to ~550 °C

Oxidative methods for sludge thermal treatment comprise incineration, wet air oxidation and supercritical water oxidation

Non-oxidative thermochemical treatment of sewage sludge refers to treatment at elevated temperatures in the absence of oxygen

Thickening, dewatering and drying extract water from sludge to reduce the sludge volume

Sludge stabilisation − alkaline stabilisation, lime and solids dosing, plus anaerobic and aerobic digestion

Sludge is the main waste stream from the treatment of wastewater