Sludge stabilisation

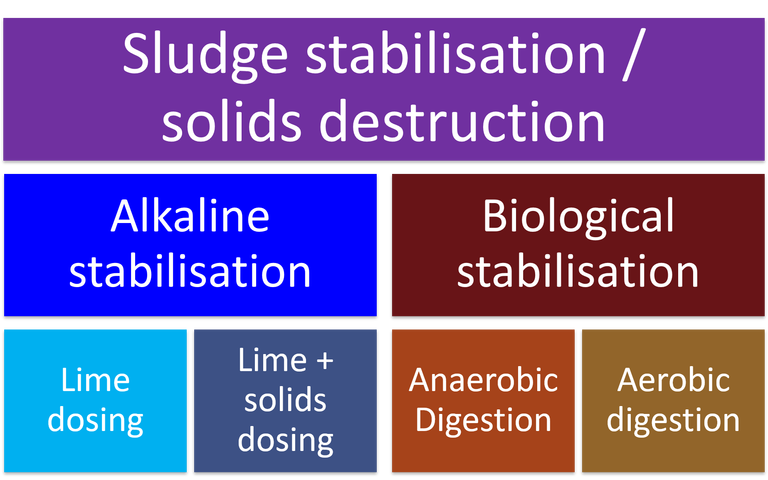

An overview of sludge stabilisation − alkaline stabilisation, lime and solids dosing, plus anaerobic and aerobic digestion

Your web browser is out of date.

Update your browser for better security, speed and to get the best experience on this website.

Alkaline stabilisation is a chemical method designed to reduce sludge odour and putrescence (i.e. decay), and the level of pathogenic organisms. This is achieved by raising the pH of the sludge using lime. The process may be supplemented by dosing with waste solid materials to reduce the amount of lime used. Although adding material to the sludge increases its volume, the process is simple, effective and low in capital cost.

An overview of sludge stabilisation − alkaline stabilisation, lime and solids dosing, plus anaerobic and aerobic digestion

Stabilisation processes reduce the odour and putrescence of sludge, and level of pathogenic organisms

Alkaline stabilisation is a chemical method to reduce sludge odour and putrescence, and the level of pathogenic organisms

Chemical stabilisation of sludge reduces its odour, putrescence and pathogenic bacteria content

A video to demonstrate the principles of the Techmatic lime slaking and dosing process.

Alkaline stabilisation reduces the sludge odour, putrescence and pathogenic organism content by raising its pH using lime

AD stabilises the sludge biologically in the absence of air, producing a useful biogas while biodegrading the organic solids

Aerobic digestion is the degradation of the organic sludge solids to carbon dioxide in the presence of oxygen

Thickening, dewatering and drying extract water from sludge to reduce the sludge volume

Thermochemical methods are used to either significantly reduce the sludge solids content or pre-treat sludge upstream of AD

Sludge is the main waste stream from the treatment of wastewater