Sludge incineration vs anaerobic digestion − the simple truth

Simon Judd

Professor Simon Judd has over 30 years’ post-doctorate experience in all aspects of water and wastewater treatment technology, both in academic and industrial R&D. He has (co-)authored six book titles and over 200 peer-reviewed publications in water and wastewater treatment.

In his capacity as director of Judd Water & Wastewater Consultants, Simon is co-owner of SludgeProcessing.com, as well as of our sister website The MBR Site. He is Professor in Membrane Technology at the Cranfield Water Science Institute at Cranfield University in the UK where he has been a staff member since 1992. Simon was also a Research Chair at Qatar University in the Middle East for six years until September 2018.

There remain, it seems, two enduring conceptions concerning sludge or biomass incineration which go like this:

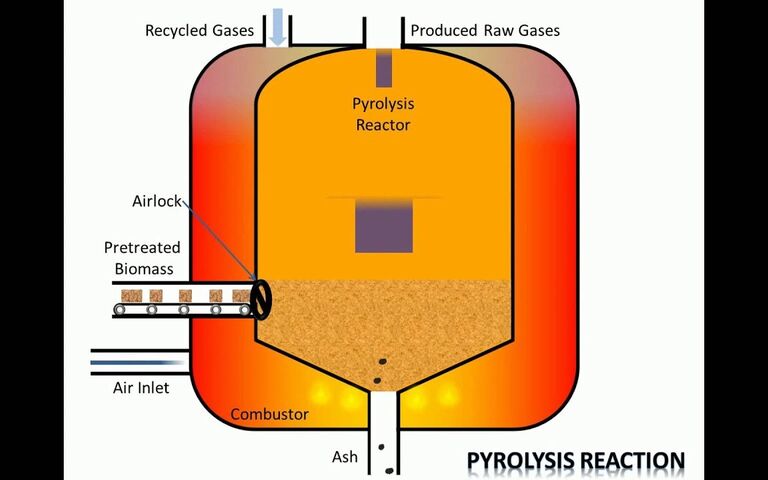

- incineration is less sustainable than anaerobic digestion (AD) or non-oxidative thermal methods (such as pyrolysis, gasification or hydrothermal processes) because they generate CO2 instead of methane as the main product

- it's also more highly polluting than the alternatives.

Let's start with the first of these, and compare incineration with AD. Both are established technologies. The recovery of biogas from AD dates back to the end of the 20th century: biogas from anaerobic digestion of sewage sludge was being used to power the street lamps of Exeter in the UK as long ago as the 1890s.

The first sludge incinerator plant was a Nichols-Herreshoff incinerator installed at Dearborn, Michigan in 1935. This was actually an excellent example of technology transfer. The Herreshoff multiple hearth furnace (the patent for which was perspicaciously acquired by Nichols Engineering) was first employed in the chemical industry in the 1880s − around the same time as the gas lamps of Exeter were being hooked up with a biogas supply. Also within this time period, the technology was being implemented for mineral ore roasting in the mining industry. But it took a little longer for the same technology to be applied to combusting sewage sludge.

So, AD and incineration have co-existed as sludge processing technologies for 85 years. Both are growing in terms of implementation. So, is incineration really the bad boy of sludge processing?

The answer, of course, is no.

Sure, AD produces lovely, natural biogas, whose principal constituent is methane, instead of nasty, ozone layer-destroying CO2. The methane can therefore be reused.

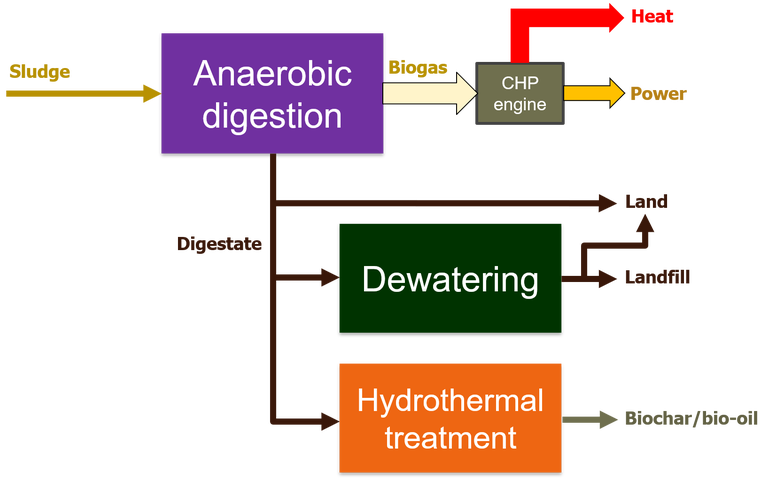

The fact is, though, the methane has to be effectively captured and prevented from being released to the atmosphere because it is roughly 20 times more greenhouse gas active − i.e. more deadly to the ozone layer − than CO2. Once captured the methane is, more often than not, fed directly into combined heat and power (CHP) engines on site which convert the methane into heat and power (the clue's in the name). And in doing so they also generate − yep, you guessed it − CO2.

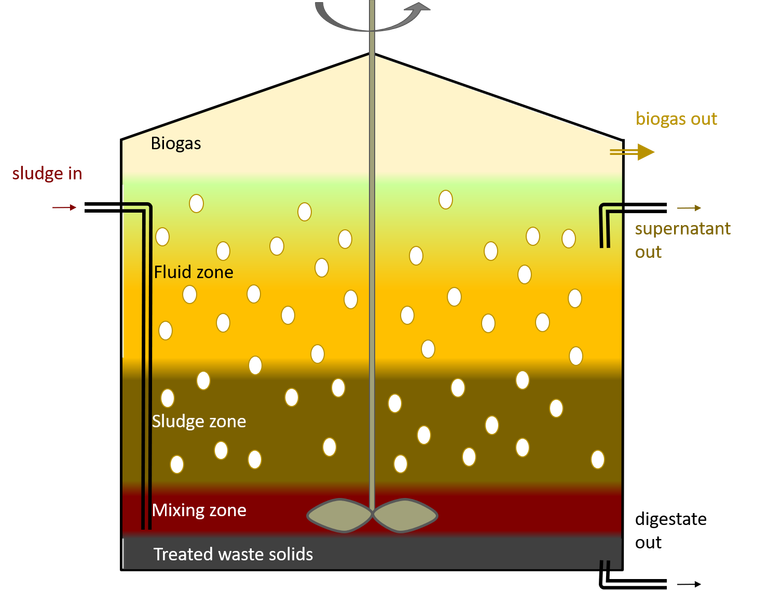

An incinerator burns the sludge directly, without it being converted to methane (which, in effect, is merely an intermediate) and converts it to useful energy in the form of heat. Part of that heat is used to power the incinerator in the same way that part of the heat from the CHP engine downstream of the AD is used to heat the AD. The key advantage of the AD is that it can be fed with thickened sludge − which has a moisture content of >90% − whereas an incinerator has to be fed with dried sludge: it becomes autothermal only at moisture contents below ~30%.

So, ultimately, the sustainability box is ticked for both these technologies − so long as the starting material is from a sustainable source. And the one thing this world is unlikely to run out of anytime soon is sewage sludge.

But what about the pollution argument? To delve into this particular perception one needs to consider the history of incineration technology development.

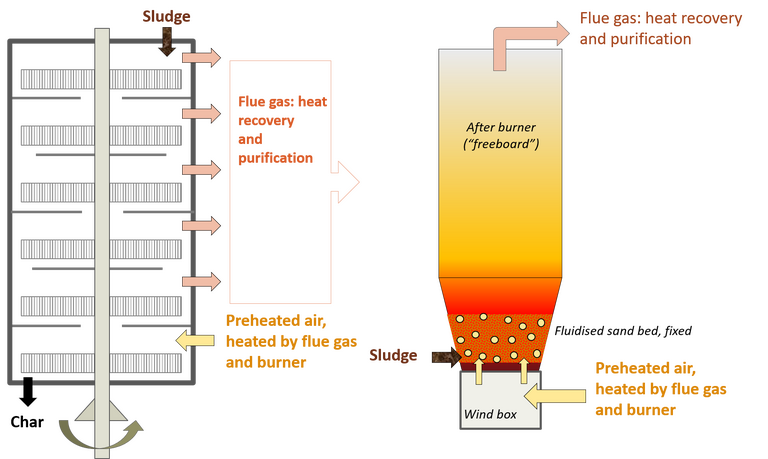

The Herreshoff MHF design for sewage sludge incineration ruled over all others for three decades from the mid 1930s. Well, actually, there were no others, since the classical MHF design was, and continues to be, very efficient in terms of sludge processed per unit land area. It is also energetically efficient in terms of converting the sludge to an ash product.

However, because the MHF operates at a relatively low temperature, it generates harmful gaseous byproducts. These can only be reduced by increasing the exhaust temperatures, demanding more energy.

Against this, the fluidised bed incinerator (FBI) has a high afterburner temperature and also provides greater combustion efficiency, with reference to the oxygen demand, than the MHF. Which is partly why a Dorr-Oliver FBI was implemented at Lynnwood, WA in 1962. This is another good example of technology transfer from the mineral mining industry. The application of the FBI configuration to the coal industry dates back to 1920s Germany, where Fritz Winkler (at BASF) and Lurgi were both working on the gasification of lignite.

The challenge to the MHF design by the FBI technology is also a classic example of the industry response to legislative drivers. Environmental legislation in the US introduced from 1963 onwards (the Clean Air Act and its subsequent amendments) meant that the existing MHFs could not meet the required flue gas discharge quality standard without modification, which increased both the capital and operating costs. Consequently, 93 FBI units were installed between 1962 and 1976, and the trend has continued to this day. Crucially, modern sludge incinerators based on the FBI technology can meet the tight atmospheric discharge limits while still being energy neutral or better.

So, arguing that incineration is more highly polluting than AD is, at the very least, debatable and ultimately likely to be untrue if considering the most modern technologies. Both effectively recover the latent energy from the sludge, both produce a solid residue (from which nutrients can be recovered) and neither rely heavily on a fossil fuel energy source.

And both ultimately generate CO2. Some things never change.