The circular economy in wastewater management – micropollutants drive the change

Peter Hillis

Peter is the founder of pH2O Consulting which works globally on water and wastewater projects including research and development, strategic planning, feasibility and concept design, detailed design and commissioning and operational optimisation. Peter is based in Melbourne, Australia and can be contacted on pH2OConsult@gmail.com

The ‘circularisation’ of the economy – where maximum value is drawn from resources at the same time as minimising waste – has been all the rage in many industries and communities, and especially so in the water industry.

The water industry has in many ways been at the forefront of sustainability for over 100 years. This is evident in the very concept of treating raw sewage to the benefit of the receiving environment to which the treated effluent is discharged. It is also evident in the production of biogas from the anaerobic digestion of biosolids for renewable energy.

The renewed interest in all things ‘circular’ by the rest of the world has encouraged a change in mindset between industrial sectors in terms of collaboration and cooperation.

This potential for collaboration across industries should be welcomed as a catalyst for the water industry − to adopt a more commercial approach to exploiting its inherent resources, and opening the industry to new technology and even more innovation. As an example, the fast-emerging hydrogen economy has already seized the opportunity presented by biomethane; the Water Corporation of Western Australia is embarking on a full-scale production facility.

Whereas in the past ‘necessity was the mother of invention’ − as evidenced by the Millennium Drought in Australia and the recent droughts in south-west USA − the circular economy concept is enabling water utilities to be more proactive in aligning their customer and business needs and realising the opportunities this creates.

But − as with all opportunities − there also come challenges.

As the world became aware of issues such as trans-gendering of aquatic species due to the presence of hormones in effluent discharged to the environment, it forced the water industry to come up with new and imaginative solutions in its drive to be ever more sustainable.

The current COVID-19 pandemic has also recently focused public attention on the monitoring of sewage for presence of the virus, and it will not be too long before concerns about pathogens and chemicals in sewage become more widely discussed.

In the same way, emerging contaminants – micropollutants – in sewage may take the driving seat in the wastewater industry’s quest for a circular economy. The public consciousness is becoming increasingly raised regarding the risks and potential dangers of micropollutants in sewage.

Two significant micropollutants are microplastics and per- and polyfluoroalkyl substances (PFAS), and these substances are already causing utilities to rethink their biosolids strategies. Microplastics and PFAS put at risk current low-cost beneficial reuse disposal options, and specifically application to agricultural land.

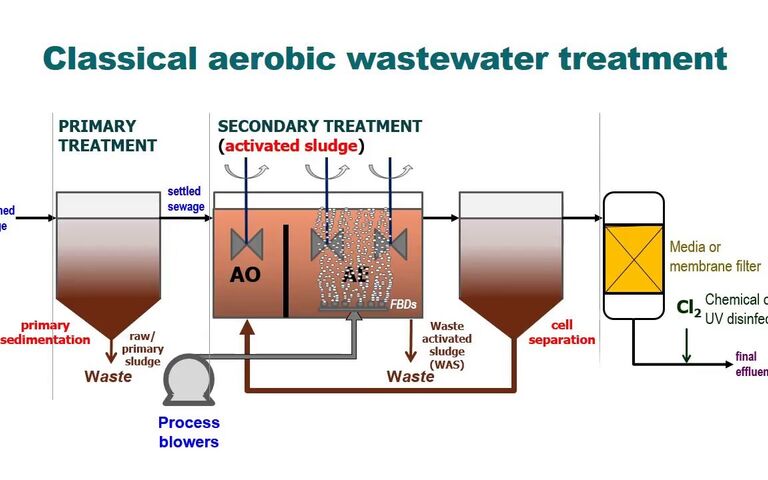

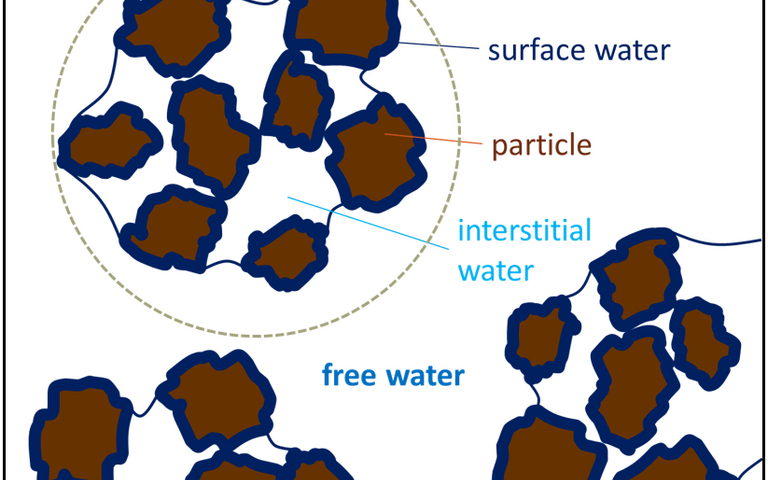

Sludge processing: the basics

Then there is also the challenge of trace levels of recreational drugs in sewage, and the public reaction to these residues if they potentially ended up in the food chain. This is a threat that could transform our approach to the management of biosolids. If standard methods of disposal to land become less viable as people become more aware of the potential harm micropollutants cause, then the industry needs to respond with innovative solutions to keep the circular economy alive.

And the industry is responding. There is increased interest, and examples of implementation, of the application of thermal processing of biosolids using gasification or pyrolysis to produce high-value products such as biochar and syngas. These technologies allow co-treatment/disposal with municipal solid waste (MSW), inviting collaboration with potential partner organisations. The Public Utilities Board (PUB) in Singapore, renowned within the water sector for its innovation in water reuse and its implementation of MBR technology in this regard, is investing in Integrated Waste Management (IWM) as it refreshes its wastewater infrastructure. Yorkshire Water in the UK has successfully demonstrated the co-gasification of its biosolids with wood chippings.

Most recently, as a result of successful gasification demonstration at Logan City Council’s Loganholme Wastewater Treatment Plant, the Australian Renewable Energy Agency (ARENA) has provided 30% of the investment for a full-scale facility. It’s a great example of how the challenge of micropollutants will drive the circular economy to experiment with thermal options rather than continue with the traditional land disposal route.

These are exciting times and in the next few years we will probably see yet more paradigm shifts in the industry, driven by the continuing need for innovation and the duty to respond to genuine community concerns.