Incineration of sludge

Introduction to sludge incineration

Incineration − or combustion − of sewage sludge is the most widely-accepted alternative end disposal method after land spreading. It is an oxidative method, converting the organic carbon, nitrogen, sulphur, nitrogen and phosphorus into gaseous and predominantly mineral (i.e. inorganic) solid products.

Example of sewage sludge incineration process, Buski

Incineration is the most established and widely implemented of the sludge thermochemical treatment processes, with the original sewage sludge incinerators installed in the mid-1930s. There are currently hundreds of large sewage sludge incinerators in operation across the world, most of which generate power as well as converting the sludge to ash.

The incineration process is effective in eliminating the feed organics, produces little odour (provided the flue gas treatment is effective), and generates a solid ash product which is stable and substantially reusable. The heat generated can be recovered from the flue gas stream and reused directly and/or converted to electrical power.

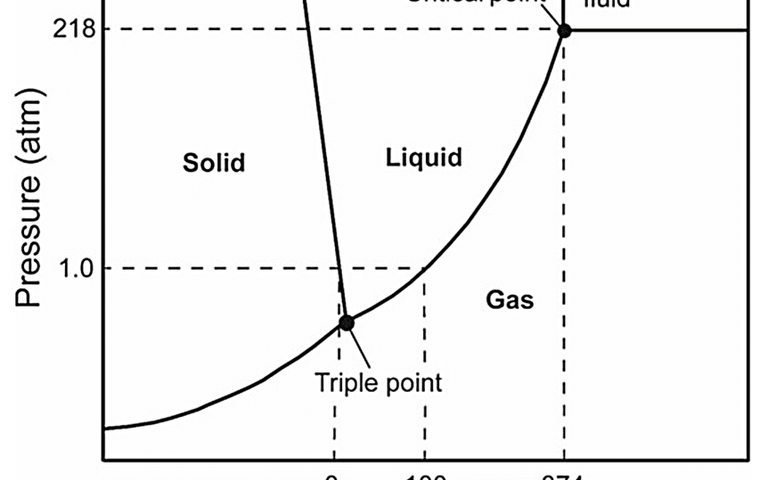

Incineration becomes autothermal (i.e. sustained by the heat generated by the combustion process) at sludge moisture contents below 33%. However, the generation of secondary pollutants such as dioxin, furans, NOx (oxides of nitrogen) and SO2 (sulphur dioxide), as well as dust particles, demands ancillary processes for removing these contaminants from the flue gas, adding to the overall cost. In addition, although most incinerators are energy-positive, the overall energy balance of the process is affected by the need to thermally dry the sludge prior to incineration.

Sludge incineration reactors are predominantly configured as fluidised beds. This configuration has largely displaced the multiple hearth furnaces originally implemented. Fluidised beds operate at a temperature of 800−900 °C and under atmospheric pressure. Particle retention times are in the order of two seconds within the reactor itself at the upflow air velocities of 0.5−1 m/s used.